Dry Ice Storage Container for Safe Transport & Reduced Sublimation

| Nome | Dry Ice Storage Container |

| Capacidade | 30-480 L |

| Insulation Core | High-Density PU Foam |

| Body Material | Rotomolded LLDPE (Food-Grade & Impact-Resistant) |

| Mobility | Equipped with durable wheels or forklift channels (model-dependent) |

| Key Features | Safety Gas Venting, Heavy-Duty Latches, Reinforced Hinges |

| Service Life | 5-8 years under standard operating conditions |

| garantia | Um ano grátis |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

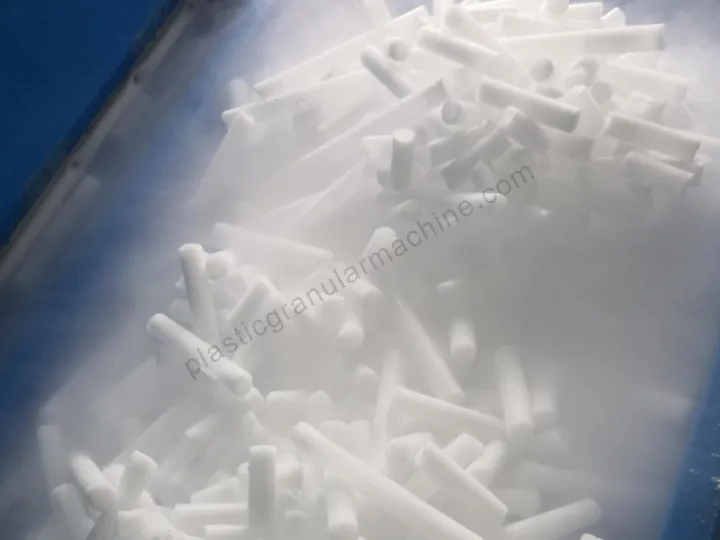

Dry ice pellets and blocks are widely used in the food cold chain, medical transport, and industrial cleaning. However, during handling and transportation, dry ice can quickly sublimate due to heat exposure, leading to material loss, safety risks, and higher operating costs.

EFFICIENT provides high-performance Dry Ice Storage Containers designed to slow sublimation, protect dry ice quality, and ensure safe, efficient cold storage.

Why Dry Ice Needs a Dedicated Storage Container

Dry ice maintains an extremely low temperature of -78.5°C. Unlike regular ice, it sublimates directly into CO₂ gas when exposed to heat or air. Using ordinary plastic boxes or foam containers often results in:

- Rapid dry ice loss

- Cracking or deformation of containers

- Unstable temperature during transport

- Increased replenishment and logistics costs

A professional dry ice storage container is therefore essential for any operation using dry ice pellets or blocks produced by a dry ice pelletizer, dry ice block press, or supplied for downstream applications such as dry ice blasting.

Key Advantages of EFFICIENT Dry Ice Storage Containers

To keep the focus clear for buyers, the advantages are summarized into four core values:

High-Efficiency Thermal Insulation

- PU rigid foam insulation with a high closed-cell structure

- Uniform density through high-pressure one-time foaming

- Slows heat transfer and significantly reduces the sublimation rate

Ultra-Low Temperature Resistant Structure

- Made from food-grade modified PE, suitable for −78.5°C

- Resistant to cracking during repeated hot–cold cycles

- Long service life under industrial conditions

Durable Rotational Molding Design

- One-piece rotomolded body and lid

- Strong impact resistance for frequent handling and transport

- Suitable for workshops, warehouses, and long-distance logistics

Secure Sealing Without Safety Risk

- Integrated sealing strips reduce cold air loss

- Designed for controlled gas release, avoiding internal pressure buildup

- Balances insulation performance and operational safety

Application Scenarios of Our Dry Ice Chest

EFFICIENT dry ice storage containers are widely used in:

- Dry ice production lines (pellets or blocks) for temporary storage

- Food cold chain logistics (seafood, frozen products, ice cream)

- Medical and pharmaceutical transport (vaccines, biological samples)

- Industrial dry ice blasting operations

- Laboratory and research cold storage

They work seamlessly with upstream equipment such as dry ice pellet machines, dry ice block machines, and dry ice blasting systems, ensuring the dry ice remains usable when it reaches the application point.

Technical Specifications of Dry Ice Cooler Boxes

| Modelo | Volume | Dry Ice Capacity | External Size (L*W*H) | Internal Size (L*W*H) |

|---|---|---|---|---|

| 30 | 30 L | 25 kg | 55*42.7*34 cm | 42.5*32.5*23.7 cm |

| 60 | 60 L | 50 kg | 46*46*93 cm | 32*32*60 cm |

| 130 | 130 L | 100 kg | 80*60*83.5 cm | 61*41*54 cm |

| 300 | 300 L | 250 kg | 110*70*101 cm | 98*55*64 cm |

| 480 | 480 L | 400 kg | 120*100*101 cm | 100*80*64 cm |

Based on Ø3 mm dry ice pellets. Capacity varies with form and packing method.

Standard design across models: Food-grade PE shell, PU insulation, sealing structure, rotomolded body.

Differences between models are mainly capacity, wall thickness, and structural reinforcement, not basic function—avoiding customer confusion

How These Containers Help Reduce Dry Ice Sublimation

After selecting the right capacity, insulation performance becomes the key factor affecting operating cost. EFFICIENT dry ice storage containers reduce sublimation by:

- Thick PU insulation minimizes heat exchange

- Tight sealing to limit warm air entry

- Stable internal structure preventing insulation gaps

- Allowing users to reduce the opening frequency during operation

In real use, proper dry ice storage can significantly extend usable time compared with ordinary containers, especially when combined with planned logistics and batch handling.

Built for Real-World Operation

Each container is designed with practical details in mind:

- Easy handling for frequent loading and unloading

- Compatibility with pallets and forklifts for large models

- Suitable for continuous use in production, transport, and storage

- Consistent performance in hot, high-humidity, or demanding environments

These details matter to buyers who focus on reliability, cost control, and long-term use, not just initial price.

Get the Right Dry Ice Storage Solution

Whether you operate a dry ice production line or use dry ice for food, medical, or industrial applications, choosing the right Dry Ice Storage Container directly affects material loss, safety, and efficiency. We offer:

- Multiple capacities from 30L to 480L

- Stable quality for export markets

- Support for matching with dry ice pelletizers, block presses, and blasting systems

Contact EFFICIENT today to get specifications, pricing, and recommendations based on your dry ice usage and logistics requirements.