Aplanadora de Vergalhões para Processamento de Barras de Aço

| Nome | Endireitador de Vergalhões |

| Matérias-primas | Barras de metal de sucata de 6-25 mm |

| Saída | Barras de aço endireitadas de 500-2000 mm |

| Motor | 4-15 kW |

| Nossos serviços | Fornecer projeto de solução, instalação no local, orientação técnica e mais. |

| garantia | Um ano grátis |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

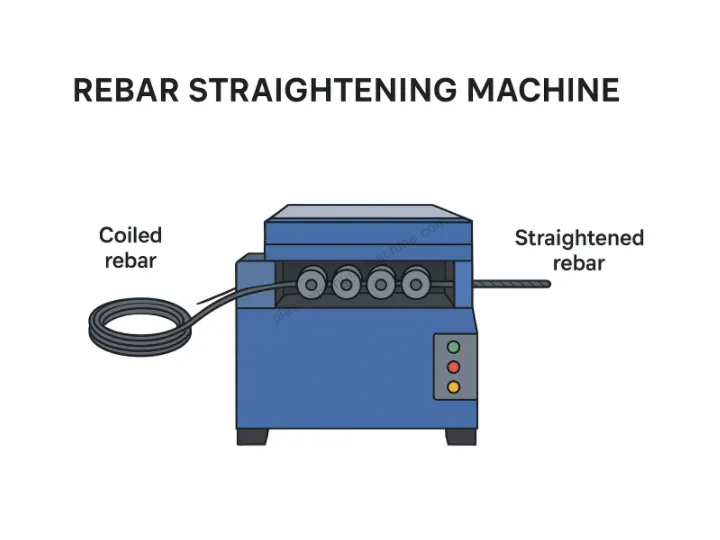

A endireitadora de vergalhões é uma máquina essencial nas indústrias de construção e processamento de aço. É principalmente usada para endireitar e processar vergalhões enrolados ou curvados em comprimentos uniformes, para posterior corte, soldagem ou uso na construção. Seja com vergalhões de diâmetro pequeno ou varões de aço pesados, uma máquina de endireitar vergalhões garante alta precisão, operação rápida e qualidade consistente do produto.

Por que precisa de uma máquina de endireitar vergalhões

Na construção moderna e na fabricação de aço, precisão e eficiência são essenciais. Vergalhões enrolados ou curvados não podem ser utilizados diretamente para reforço; devem ser endireitados primeiro.

É aí que entra um endireitador de vergalhões — transforma bobinas embaraçadas em barras de aço perfeitamente retas, prontas a usar. Escolher uma máquina de endireitar vergalhões fiável garante operações mais suaves, qualidade consistente e custos de mão-de-obra mais baixos.

Matérias-primas e produtos acabados da nossa endireitadora de vergalhões

A máquina de endireitar vergalhões de aço é projetada para lidar com várias matérias-primas, tais como:

- Vergalhões enrolados (6-25 mm)

- Varões de aço deformados ou curvados

- Barra de metal redonda e fios de aço

Após o endireitamento, os produtos finais apresentam:

- Superfície lisa e uniforme sem deformação

- Comprimento de corte preciso (comummente 500-2000 mm)

- Pronto para soldar, construção ou reprocessamento

Estes vergalhões acabados são ideais para betão armado, produção de aço estrutural e indústrias de fabricação.

Como funciona a endireitadora de vergalhões

Dentro da máquina endireitadora de vergalhões, a barra de aço passa por um conjunto de rolos precisamente dispostos que giram em alta velocidade.

Cada barra é corrigida várias vezes (tipicamente 5-6 furos, 20 passes por ciclo) para remover torções e curvas.

A máquina de endireitar barras alimenta automaticamente a barra numa unidade de corte, onde é cortada ao comprimento predefinido.

O processo é totalmente automático — combina endireitamento, medição e corte numa única operação contínua. Isto não só melhora a precisão, mas também aumenta a produtividade das linhas de processamento de aço.

Vários modelos de máquinas de endireitar vergalhões disponíveis

A nossa endireitadora de bobinas de vergalhões oferece vários modelos para diferentes diâmetros de vergalhões e necessidades de produção. Também podemos fornecer endireitadoras personalizadas para as suas necessidades. (Por favor, sinta-se à vontade para contactar-nos)

| Modelo | Diâmetro de endireitamento (mm) | Orifícios de endireitamento | Comprimento de Corte (mm) | Potência do Motor (kW) | Peso da máquina (kg) | Máquina Dimensão (mm) |

|---|---|---|---|---|---|---|

| ET-6-10 | 6-10 | 5 orifícios*20 passes | 500-2000 | 4 | 570 | 1100*720*1150 |

| ET-6-14 | 6-14 | 5 orifícios*20 passes | 500-2000 | 5 | 730 | 1200*790*1220 |

| ET-8-16 | 8-16 | 5 orifícios*20 passes | 500-2000 | 5 | 750 | 1250*820*1300 |

| ET-14-25 | 14-25 | 6 orifícios*20 passes | 500-2000 | 15 | 980 | 1550*890*1600 |

Configurações personalizadas disponíveis para diâmetros maiores ou materiais de aço específicos.

Por que a Qualidade Importa — Máquinas de Endireitar Boas vs. Máquinas de Endireitar Mau

Nem todas as endireitadoras de vergalhões são iguais.

Máquinas de baixa qualidade muitas vezes resultam em vergalhões curvados, superfícies ásperas, frequentes paragens e cortes imprecisos — desperdiçando matérias-primas e aumentando os custos de manutenção. Em contrapartida, uma máquina de endireitar vergalhões de alta qualidade fornece:

- Barras perfeitamente retas com superfícies limpas e suaves

- Comprimento de corte consistente com desperdício mínimo

- Operação estável e longa duração

- Alta velocidade de trabalho e rolos de precisão

É por isso que construtores profissionais e processadores de aço escolhem a nossa endireitadora hidráulica de vergalhões — fabricada com rolos duráveis, quadros pesados e sistemas de controlo de precisão.

Nosso compromisso de qualidade e serviço

Na EFFICIENT, projetamos cada máquina de endireitar barras de metal para desempenho e fiabilidade.

Prometemos:

- Operação estável e qualidade testada antes da entrega

- Soluções personalizadas para tamanhos de vergalhões de aço e necessidades de produção

- Envio rápido mundial e documentação completa

- Orientação técnica e apoio de peças sobressalentes

O nosso objetivo é ajudar os clientes a alcançar maior eficiência, melhor qualidade e fiabilidade a longo prazo.

Aplicações típicas da máquina de endireitar vergalhões de aço

A endireitadora de barras redondas é amplamente utilizada em:

- Fábricas de construção e processamento de vergalhões

- Oficinas de fabricação de aço

- Linhas de produção de betão pré-fabricado

- Centros de reciclagem de metal

É ideal para endireitar aço suave, vergalhões deformados, barras redondas e varões de metal.

Conclusão

Uma endireitadora de vergalhões é um investimento essencial para qualquer negócio de aço ou construção. Com uma máquina hidráulica de endireitar vergalhões, pode produzir vergalhões uniformes, precisos e suaves — mais rápido e com custos mais baixos.

Por favor, sinta-se à vontade para nos contactar. Escolha a nossa endireitadora de vergalhões para garantir desempenho duradouro e suporte profissional!