Шлифовальный станок для шин и магнитные сепараторы | Производство резинового порошка

| Имя | шинный шлифовальный станок и магнитные сепараторы |

| Функция | измельчение резинок в порошок |

| Емкость | 80-2300 кг/ч |

| Ввод | Шины 30-100 мм / целые шины |

| Выход | Резиновый порошок 5-40 меш |

| Чистота | Более 99% |

| Гарантия | Один год |

| Услуги | Руководства по эксплуатации, установка на месте и т. д. |

Теперь вы можете уточнить технические подробности у наших менеджеров проектов.

Наш шредер для шин и магнитные сепараторы эффективно перерабатывают куски шин размером 30-100 мм в резиновый порошок с размером частиц 5-40 меш, одновременно автоматически отделяя стальные проволоки, что максимизирует чистоту и потенциальную прибыль. С потреблением энергии, сниженном на 1/3, и моделями с производительностью от 80 кг/ч до 2300 кг/ч, мы обеспечиваем лидирующую рентабельность инвестиций для глобальных переработчиков.

Сырье и премиум-продукция системы шлифовки шин

Наши измельчители шин и магнитные сепараторы тщательно спроектированы для беспрепятственной интеграции как в полуавтоматические, так и в полностью автоматические линии по переработке отработанных шин. Эта универсальность позволяет эффективно перерабатывать широкий спектр типов шин, включая стандартные шины (диаметром <1200 мм) и более крупные шины Off-the-Road (OTR). В конфигурации линии по переработке шин система обрабатывает следующие входные и выходные данные:

- nullВход:Целые/измельченные шины (блоки 30-100 мм).

- nullВыход:null

- мелкий резиновый порошок 5-40 сетки (0,63 мм–2,5 мм)

- Чистая стальная проволока (восстановленная с помощью магнитного сепаратора)

Нет необходимости в ручной сортировке – чистый выход за один проход.

Почему наши машины для резинового порошка популярны на рынке?

- Высокоэффективный интегрированный дизайнкомпактную систему, которая сочетает в себе дробление, сортировку и магнитное разделение для обеспечения упрощенной и эффективной переработки.

- Регулируемый размер порошка: Резиновый порошок можно свободно регулировать в диапазоне от 5 до 40 меш, подходящие для различных применений, таких как переработанные резинотехнические изделия, спортивные покрытия и коврики.

- Широкий диапазон мощности: Производственная мощность варьируется от 80 кг/ч до 2300 кг/ч, что делает их идеальными для небольших мастерских, средних производств и крупных промышленных перерабатывающих заводов.

- Эффективное удаление стали: Оснащен встроенным мощным магнитным барабаном, которые эффективно удаляют мелкие стальные проволоки из резинового порошка.

- Высокая чистота выходаФинальная резиновая пудра достигает чистоты не менее 99%, обеспечивая более высокое качество для последующих применений.

Технические характеристики нашей линии шлифовки резинок для шин

| nullРазмер выходаnull | nullШинный шлифовщик SL-350null | nullРезиновый гранулятор SL-400null | nullШинный шлифовщик SL-450null | nullСистема магнитного сепаратора SL-560null | nullПромышленный шлифовщик SL-560Dnull | nullСЛ-660 Высокопроизводительная мельницаnull |

|---|---|---|---|---|---|---|

| null10 Меш (2.5мм)null | 250-300 кг/ч | 400-500 кг/ч | 500-600 кг/ч | 900-1000 кг/ч | 1500-1600 кг/ч | 2100-2300 кг/ч |

| null20 Меш (1.25мм)null | 180-230 кг/ч | 300-350 кг/ч | 400-500 кг/ч | 600-700 кг/ч | 1200-1300 кг/ч | 1600-1700 кг/ч |

| null30 Меш (0.83мм)null | 150-210 кг/ч | 240-280 кг/ч | 350-450 кг/ч | 450-550 кг/ч | 1000-1100 кг/ч | 1200-1300 кг/ч |

| null40 Меш (0.63мм)null | 80-120 кг/ч | 150-175 кг/ч | 200-250 кг/ч | 300-350 кг/ч | 800-900 кг/ч | 900-1000 кг/ч |

| nullВосстановление стальной проволокиnull | ✅ Интегрированный магнитный сепаратор | ✅ Автоматическое разделение | ✅ Непрерывное удаление | ✅ Высокая мощность извлечения | ✅ Двухступенчатое разделение | ✅ Устойчивое восстановление |

| nullНастройка мощностиnull | 220В/380В/415В | Глобальная поддержка напряжения |

- Встроенный магнитный сепаратор: Эффективно удаляет 99% стальной проволоки в процессе шлифования.

- Энергосбережение: потребление на 30% ниже по сравнению с обычными машинами

- Гарантия на ролики: 3-летняя гарантия на ролики из сплава 5Cr6MnMo

- Диапазон выходной продукции: 5-40 меш (Доступны настраиваемые экраны)

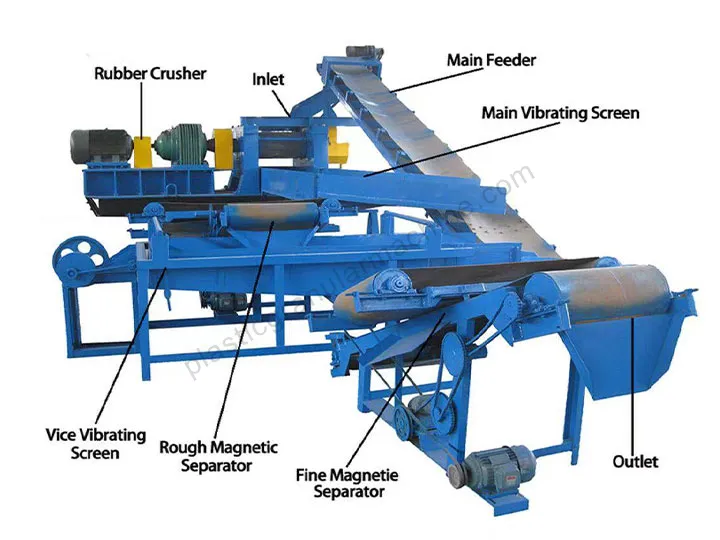

Как работает мельница для шин и магнитный сепаратор?

- nullГрубое дробление:После измельчения, резинотехнические изделия подаются в ребристые валы.

- nullГрануляция:Регулируемые стадии измельчения уточняют частицы.

- nullСепарация:Магнитные ролики извлекают стальную проволоку.

- nullСкрининг:Вибрационные сита классифицируют порошок (10-40 меш).

Ключевые технические характеристики:

- Двойные канавочные ролики (отношение скорости 1:2.5)

- 8 подшипников для стабильности

- Ролики из сплава 5Cr6MnMo (гарантия 3 года)

- Полная защита и система смазки

Применения линии шлифовки шин

Наша шлифовка шин на продажу может широко использоваться для:

- Центры переработки стальной проволоки

- Заводы по регенерации резины

- Покрытие для спортивных дорожек и детских площадок

- Асфальт с модификацией резиной

- Промышленный резиновый мат\/формовка

Почему стоит выбрать нашу шлифовку шин?

- Годовая гарантия бесплатно.

- Настройка напряжения (220В\/380В\/415В)

- На 30% меньше потребление энергии по сравнению с конкурентами

- Производство с сертификатами CE и ISO

- Доступны услуги по установке на месте и техническому руководству.

Если вы ищете хорошее решение для улучшения вашего бизнеса по переработке шин, пожалуйста, свяжитесь с нами. Мы порекомендуем вам наиболее подходящий метод переработки отработанных шин!