Hydraulische Metallpresse für effizientes Schrottrecycling

| Name | Metallpresse |

| Rohstoffe | Verschiedene Metallschrott |

| Endprodukte | hochdichte reguläre Ballen |

| Leistung | 15-90 kW |

| Ballenlänge | 30-60 cm |

| Ballengewicht | 30-1500 kg |

| Garantie | Ein Jahr |

| Dienst | Bedienungsanleitungen, Installation vor Ort usw. |

Sie können jetzt unsere Projektmanager nach technischen Details fragen

Suchen Sie nach einer effizienten Lösung, um Ihr Metallschrott zu komprimieren und Lager- sowie Transportkosten zu senken? Unser hydraulischer Metallpressen ist Ihre ideale Wahl – leistungsstark, anpassbar und langlebig.

Was ist eine hydraulische Metallpresse?

Eine hydraulische Metallpresse ist eine spezialisierte Recyclingmaschine, die entwickelt wurde, um verschiedene Metallschrottsorten in kompakte, dichte Ballen zu pressen. Angetrieben durch hydraulischen Druck gewährleistet dieses Gerät einen hocheffizienten Betrieb in Schrottplätzen, Recyclingzentren, Metallverarbeitungsanlagen und Schmelzindustrien.

Eingabematerialien und fertige Ballentypen

Unsere hydraulischen Metallpressen können eine Vielzahl von eisenhaltigen und nichteisenhaltigen Metallen verarbeiten, einschließlich:

- Schrottstahl und Eisen

- Aluminiumdosen und -bleche

- Kupferdrähte und -rohre

- Stahlspäne und Aluminiumspäne

- Autokarosserien, Ölfässer und demontierte Geräte

Die fertigen Ballen können rechteckig, zylindrisch oder sogar achteckig sein, je nach Größe Ihres Ofens oder Ihren Lagerpräferenzen.

Anwendungen unserer hydraulischen Metallpresse

Diese Ausrüstung wird häufig verwendet in:

- Schrottmetall-Recyclinganlagen

- Metallverarbeitungs- und -herstellungsanlagen

- Stahlwerke und Gießereien

- Autoverwertungsanlagen

- Abfallsortierzentren

Durch die Umwandlung von losem Schrott in hochdichte Ballen wird der Transport erleichtert, der Oxidationsverlust während des Schmelzprozesses verringert und die Ofenfülleffizienz verbessert.

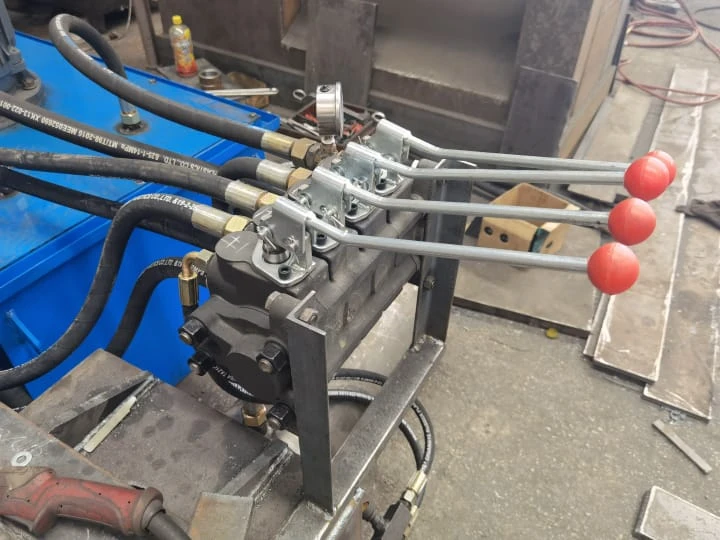

Hauptmerkmale der hydraulischen Presse

Die hydraulischen Metallpressen von Shuliy sind mit Benutzerfreundlichkeit und Effizienz im Hinterkopf konzipiert:

- hydraulisch betriebene AnlagenGlatte, stabile und energieeffiziente.

- Flexible Steuerungsmodi: Wählen Sie zwischen manueller Steuerung und PLC-Automatisierung.

- Mehrere Ballenauswurfmethoden: Seiten- und Frontschub sowie Ballenwenden, um verschiedenen Materialtypen gerecht zu werden.

- Keine Fundamentierung erforderlich: Einfache Installation, auch in abgelegenen Gebieten. Dieselbetriebene Versionen sind ebenfalls erhältlich.

- Kompakte und langlebige Struktur: Entwickelt für den kontinuierlichen Betrieb und minimalen Wartungsaufwand.

Egal, ob Sie mit leichten Aluminiumschrott oder schweren Industrie-Metallen zu tun haben, wir haben Modelle von 125 bis 400 Tonnen, um Ihren Produktionsanforderungen gerecht zu werden.

Parameter der Schrottballenpresse zum Verkauf

| Modell | Y81- 125 | Y81- 135 | Y81- 160 | Y81- 200 | Y81- 250 | Y81- 315 | Y81- 400 |

| Hydraulischer Druck | 125 T | 135 T | 160 T | 200 T | 250 T | 315 T | 400 T |

| Ballengröße | 30*30 cm | 30*30 cm | 35*35/40*40 cm | 45*45 cm | 50*50 cm | 50*50/60*60 cm | 60*60 cm |

| Ballengewicht | 30-50 kg | 30-50 kg | 50-180 kg | 100-200 kg | 200-800 kg | 700-1500 kg | 1000-1500 kg |

| Zykluszeit | 100 s | 110 s | 110-130 s | 140 s | 150-160 s | 170-200 s | 180 s |

| Motorleistung | 15 kW | 18,5 kW | 18,5 / 22 kW | 22 kW | 44 kW | 60 kW | 90 kW |

| Silo Volumen | 300 L | 300 L | 300/600 L | 600 L | 800-1000 L | 1000-1500 L | 1500 L |

Wie funktioniert die Metall-Schrottpressmaschine?

Die hydraulische Metallpresse arbeitet durch eine Reihe von Hydraulikzylindern:

- Füttern: Metallschrott wird manuell oder über ein Förderband in die Verdichtungskammer geladen.

- KompressionDas hydraulische System aktiviert sich und komprimiert das Material mit Hochdruckzylindern.

- AusstoßSobald der Ballen geformt ist, wird er mit der gewählten Methode - umdrehen, vorne oder seitlich schieben - ausgeworfen.

Das intelligente Steuerungssystem des Ballens sorgt für gleichmäßige Ballengrößen und hohe Durchsatzraten, was sowohl Zeit als auch Arbeitskraft spart.

Kundenspezifische Schrottmetallpresse zu verkaufen

Sind Sie bereit, Ihren Metallrecyclingprozess zu optimieren? Kontaktieren Sie uns jetzt für eine maßgeschneiderte hydraulische Metallballenpressenlösung! Darüber hinaus bieten wir neben der Metallballenpressung auch Kunststoffballenpressen für das Recycling an.