タイヤグラインダーと磁気分離器| ゴム粉製造

| 名前 | タイヤグラインダーと磁気セパレーター |

| 関数 | ゴムブロックを粉末に粉砕する |

| 容量 | 80-2300 kg/h |

| 入力 | 30-100 mm タイヤブロック/全体のタイヤ |

| 出力 | 5-40 メッシュのゴム粉 |

| 純度 | 99%以上 |

| 保証 | 1年 |

| サービス | 操作ガイド、現場での設置など。 |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

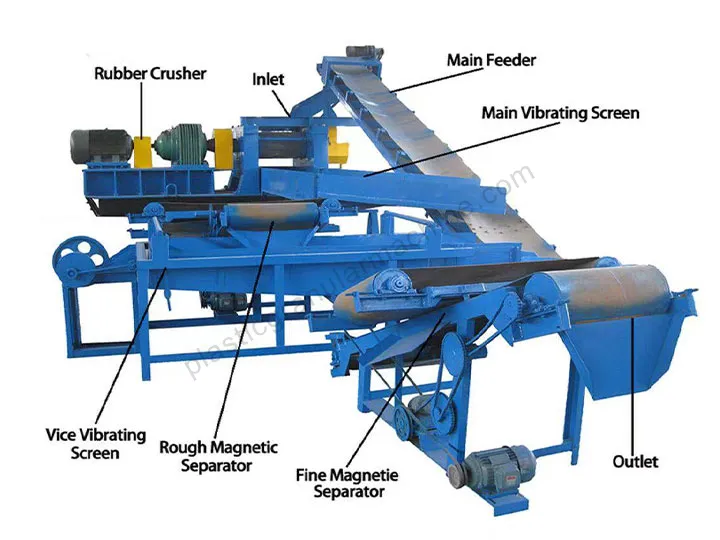

当社のタイヤグラインダーと磁気分離機は、30-100mmのタイヤの塊を5-40メッシュのゴム粉に効率的に変換し、同時に鋼線を自動的に分離します。これにより、純度と利益の可能性を最大化します。エネルギー消費は1/3削減され、80kg/hから2300kg/hまでのモデルを展開しており、グローバルなリサイクラーに業界トップのROIを提供します。

タイヤグラインダーシステムの原材料とプレミアム出力

当社のタイヤグラインダーおよび磁気分離機は、半自動および全自動廃タイヤリサイクルラインの両方にシームレスに統合できるように細心の注意を払って設計されています。この汎用性により、標準タイヤ(直径1200mm未満)や大型のオフロード(OTR)タイヤを含む、さまざまな種類のタイヤを効率的に処理できます。タイヤリサイクルラインの構成内で、システムは次の入力と出力を処理します。

- null入力:全体/粉砕されたタイヤ(30-100mmブロック).

- null出力:null

- 5-40メッシュ(0.63mm–2.5mm)の細かいゴム粉

- クリーンなスチールワイヤー(磁気分離器を介して回収)

手動での選別は不要 – 一度の通過で純粋な出力。

なぜ私たちのゴム粉砕機は市場で人気があるのか?

- 高効率統合設計:粉砕、ふるい分け、磁気分離を1つのコンパクトなシステムに統合し、効率的な処理を確保します。

- 調整可能な粉末サイズ:ゴム粉は自由に調整可能です 5メッシュから40メッシュまで、リサイクルゴム製品、スポーツフロア、マットなど、さまざまな用途に適しています。

- 広い容量範囲:生産能力は以下の範囲です 80 kg/hから2300 kg/h、小規模な作業場、中規模の施設、大規模な産業リサイクルプラントに最適です。

- 効率的な鋼の除去:内蔵の強力な磁気ドラムを搭載 高純度出力、ゴム粉から細いスチールワイヤーを効果的に除去します。

- 高純度出力最終ゴム粉は 純度99%以上を達成します、下流の用途に対してより高い品質を確保します。

私たちのゴムタイヤグラインダーラインの技術仕様

| null出力サイズnull | nullSL-350タイヤグラインダーnull | nullSL-400ゴムグラニュレーターnull | nullSL-450タイヤグラインダーnull | nullSL-560 磁気分離器システムnull | nullSL-560D 工業用グラインダーnull | nullSL-660 高容量ミルnull |

|---|---|---|---|---|---|---|

| null10メッシュ(2.5mm)null | 250-300 kg/h | 400-500 kg/h | 500-600 kg/h | 900-1000 kg/h | 1500-1600 kg/h | 2100-2300 kg/h |

| null20メッシュ(1.25mm)null | 180-230 kg/h | 300-350 kg/h | 400-500 kg/h | 600-700 kg/h | 1200-1300 kg/h | 1600-1700 kg/h |

| null30メッシュ(0.83mm)null | 150-210 kg/h | 240-280 kg/h | 350-450 kg/h | 450-550 kg/h | 1000-1100 kg/h | 1200-1300 kg/h |

| null40メッシュ (0.63mm)null | 80-120 kg/h | 150-175 kg/h | 200-250 kg/h | 300-350 kg/h | 800-900 kg/h | 900-1000 kg/h |

| null鋼線回収null | ✅ 統合型磁気分離器 | ✅ 自動分離 | ✅ 連続除去 | ✅ 高出力抽出 | ✅ 二段階分離 | ✅ 重負荷回収 |

| null電力カスタマイズnull | 220V/380V/415V | グローバル電圧サポート |

- 内蔵型磁気セパレーター:粉砕プロセス中に99%のスチールワイヤーを効果的に除去します。

- 省エネルギー従来の機械と比較して消費量が30%低いです

- ローラー保証:5Cr6MnMo合金ローラーの3年保証

- 出力範囲:5-40メッシュ(カスタマイズ可能なスクリーンあり)

タイヤミルと磁気分離器はどのように機能するのか?

- null粗砕:後に 粉砕されたタイヤブロックは溝のあるローラーに供給されます。

- null粒度調整:調整可能な粉砕段階が粒子を精製します。

- null分離:磁気ローラーが鋼線を抽出します。

- nullスクリーニング:振動ふるいは粉末を分類します(10-40メッシュ)。

主な技術のハイライト:

- デュアルグルーブローラー(速度比 1:2.5)

- 安定性のための8つの転がり軸受

- 5Cr6MnMo合金ローラー(3年保証)

- 完全保護カバーと潤滑システム

タイヤ粉砕ラインの用途

私たちの販売用タイヤグラインダーは、以下の用途に広く使用できます:

- 鋼鉄ワイヤーリサイクルセンター

- ゴム再生プラント

- スポーツトラック&遊び場の床材

- ゴム改質アスファルト

- 工業用ゴムマット/成形

なぜ私たちのタイヤグラインダーを選ぶのか?

- 1年間の無料保証。

- 電圧カスタマイズ(220V/380V/415V)

- 競合他社に対して30%のエネルギー使用量削減

- CE、ISO認証取得の製造

- 現地設置サービスと技術指導が利用可能です。

タイヤリサイクルビジネスを改善するための良いソリューションをお探しの場合は、お気軽にお問い合わせください。あなたに最適な廃タイヤリサイクル方法をお勧めします!