半自動タイヤリサイクル生産ライン

| 名前 | 半自動タイヤリサイクル生産ライン |

| 原材料 | ≤1200 mm タイヤ |

| 最終製品 | 10-40メッシュ(0.63-2.5 mm) ゴム粉 |

| 容量 | カスタマイズされた |

| 保証 | 1年間無料 |

| サービス | テクニカルサポートとオンサイト設置。 |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

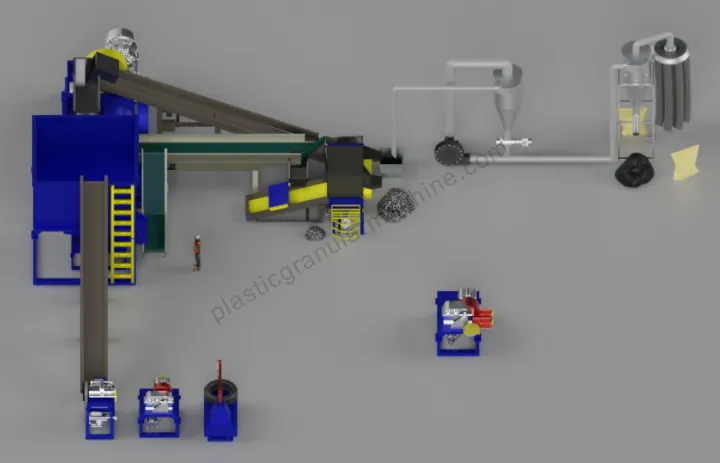

半自動タイヤリサイクル生産ラインは、手動支援と自動化機器の相乗的な操作を組み合わせて、廃タイヤをコスト効率の良い方法でゴム粉に変換することを実現します。

一般的な廃タイヤ、例えば自動車のタイヤをリサイクルするために広く使用でき、2〜4人だけで操作できるため、特に限られた予算のスタートアップや中小規模のタイヤリサイクル工場に適しています。

タイヤリサイクル生産ラインの応用と最終製品

セミオートマチックタイヤリサイクル生産ラインは、直径が1200mm以下のすべての種類の廃タイヤ(自動車用タイヤ、トラック用タイヤなど)を処理するのに適しています。

前処理、粉砕、研磨、ふるい分けのプロセスを通じて、廃タイヤは10-40メッシュの調整可能なゴム粒子または粉末に加工され、製品の純度は99%以上に達します。

廃タイヤリサイクルラインの主な特徴

- 低投資: シンプルな構造、柔軟な操作、低い購入コスト、スタートアップや小規模工場に適しています。

- 高リターン: 高効率、良好な製品品質、純度99%、市場での競争力が高いです。

- 簡単な操作: 生産を完了するのにわずか2-4人で済みます。設備には安全ガードが装備されており、安全に操作できます。

- 環境保護: CEおよびISO証明書を提供でき、低エネルギー消費、無公害、環境基準に適合しています。

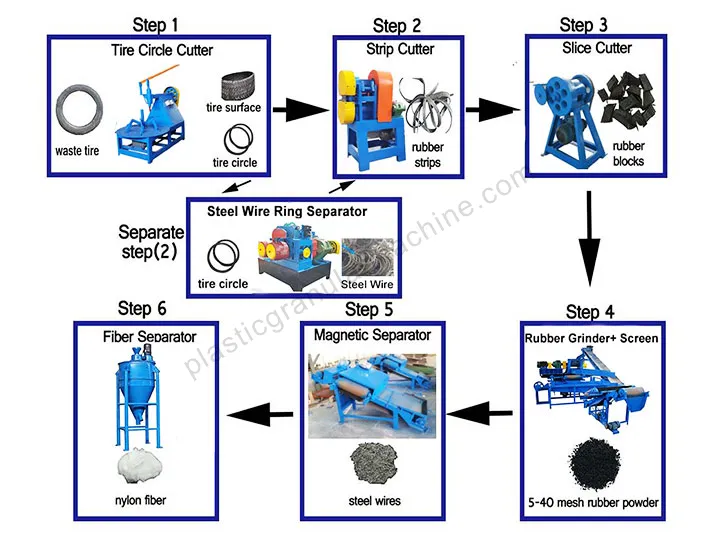

半自動ゴム粉生産ラインはどのように機能しますか?

完全な半自動廃タイヤリサイクルラインは、タイヤサイドウォールカッター、タイヤストリップカッター、タイヤブロックカッター、タイヤシュレッダー、ゴム粉砕機、磁気分離システム、そして繊維分離機で構成されています。

- 前処理 1タイヤリングカッター機を使用して、大量のスチールワイヤーを含むタイヤビードを切り取り、ゴムタイヤのサイドウォールを取得します。

- 前処理 2: タイヤストリップカッティングマシンを利用して、タイヤのサイドウォールを3-5 cm幅のストリップに切ります。

- 前処理 3: 次に、タイヤブロックカッターでゴムストリップを5 cmの長さと幅の小さなブロックに切り、次の粉砕プロセスに備えます。

- 粉砕とふるい: ツインローラーは、せん断と摩擦を通じてゴムブロックを10-40メッシュの粉末に効率的に粉砕します。振動スクリーンと多段階のふるいシステムが自動的に合格した粉末を分離し、サイズ要件を満たさない材料を再利用します。

- 磁気分離: 磁気ローラー吸着を通じて、ゴム粉の中の混合鉄線を効率的に除去し、ゴム粉の純度を向上させます。

- 繊維分離: 残留ナイロン繊維は、空気流スクリーンによって除去され、ゴム粉の純度が99%を超えることが保証されます。

販売用の効率的なタイヤリサイクル機械

当社のタイヤリサイクル生産ラインはモジュール式で柔軟性があります。以下は各機械の主要な仕様に関する情報です。

タイヤサイドウォールカッティングマシン

鋼線の除去に非常に効率的で、全体のラインの寿命を保護し延ばします。

- 処理能力: 40 個/時

- モーター出力: 4+0.75 KW

- 作業範囲: 650-1250 mm タイヤ

- 機械サイズ:1.8m*1.3m*1.6m

タイヤストリップカッター

強力な切断力、簡単な操作、小さなフットプリント。

- 容量:1000 kg/h

- モーター出力:5.5 KW

- モーター速度:45 r/min

- 最終製品:幅3-5 cmのストリップ

タイヤブロックカッター

安定した切断はタイヤリサイクル効率を効果的に向上させ、後続装置を保護し、連続運転に適しています。

- モデル: QKJ-358、更新されたタイヤブロックカッター

- 能力: 800/1500 kg/h

- モーター出力: 5.5/18.5 KW

タイヤグラインダーとマグネティックセパレーター

Fine grinding, multi-stage screening, uniform and fine material, adjustable size, purity greater than 99%.

- モデル: SL-350/400/450/560/560D/660ライン

- 能力:80-300 / 150-400 / 200-600 / 300-1000 / 800-1600 / 900-2300 kg/h

- 出力サイズ: 10-40メッシュ (2.5-0.63 mm)

ファイバーセパレーター

ナイロン繊維の高効率な除去、ゴム粉への損傷なし、省エネで環境に優しい。

- 容量:800-1000 kg/h

- モーター出力:5.5 KW

- 出力純度:99%以上

カスタマイズされたタイヤリサイクルソリューションを手に入れよう!

タイヤリサイクル事業を始めたばかりでも、すでに成熟したリサイクルプラントを運営している場合でも、半自動から完全自動のタイヤリサイクル生産ラインまで、あらゆるタイプのタイヤに合わせたカスタマイズソリューションを提供します。詳しくはお気軽にお問い合わせください!