Máquina de Corte de Resíduos Têxteis para Uso em Fábricas de Reciclagem de Fibra

| Nome | Máquina de corte de tecido de fibra |

| Capacidade | 300-5000 kg/h |

| Tamanho do corte | 5-300 mm |

| Serviço | orientação técnica, instalação no local, etc. |

| garantia | Um ano |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

A nossa máquina de corte de resíduos têxteis é ideal para reciclar materiais têxteis como retalhos de algodão, fibras de poliéster, roupas velhas, etc. Com uma capacidade de 300–5000 kg/h, ela corta eficientemente os resíduos para uma reciclagem posterior das fibras. Graças ao seu design durável e saída limpa, é amplamente utilizada em fábricas têxteis e plantas de fibras em todo o México, Marrocos, Sri Lanka e mais.

Função da Máquina de Corte de Resíduos de Tecido de Fibra

Escopo de Aplicação

A máquina de corte de fibra têxtil é amplamente utilizada nas seguintes indústrias:

- Fábricas têxteisCorte de tecido sobressalente, resíduos de fio e acabamentos de borda.

- Fábricas de vestuárioProcessamento de restos de algodão e roupas velhas para reciclagem.

- Plantas de reciclagem de fibrasPreparação de resíduos têxteis para abertura, peletização ou re-fiação.

- Processadores de materiais não tecidosDestruição de folhas de fibra macia e rolos não tecidos.

- Recicladores de roupas em segunda mão: Cortando roupas usadas em pedaços de fibra uniformes.

Esta máquina de corte de resíduos têxteis é ideal para manusear grandes volumes de algodão, poliéster e outros resíduos de tecidos macios.

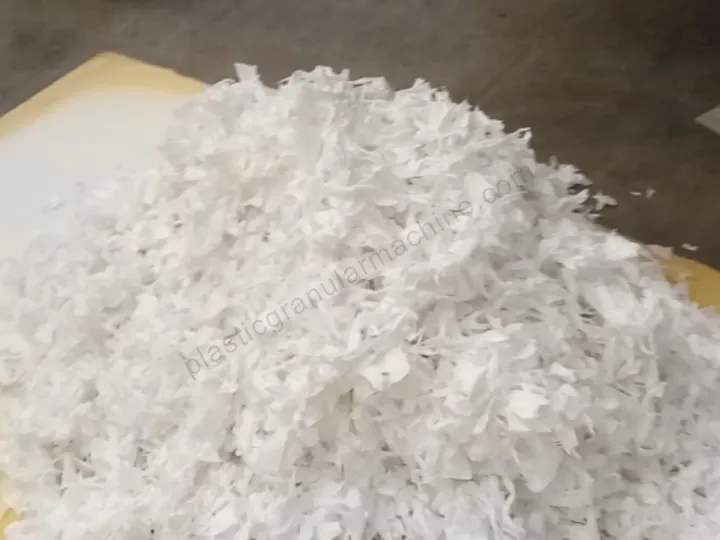

Produtos Finais

O tamanho da saída da fibra pode ser ajustado de 5 a 300 mm e apresenta:

- O comprimento é uniforme e ajustável.

- Não se embaraça facilmente, é altamente fofa e fácil de abrir.

- As bordas são limpas e livres de poeira, sem marcas de queimadura.

- Pode ser alimentada diretamente em uma máquina de abertura de fibra ou em outros equipamentos subsequentes para processamento.

- Possui amplas aplicações em materiais de isolamento térmico, acolchoamento, fibras renováveis e mais.

Principais Características da Máquina Automática de Corte de Tecido

- Aplicação Versátil – Adequada para vários materiais fibrosos; compatível com diferentes linhas de reciclagem têxtil.

- Lâminas Duráveis – Equipado com lâminas de aço ferramenta de liga de alta qualidade para excelente dureza e resistência ao desgaste.

- Alta Eficiência de Corte – Utiliza um design avançado de fresa de torque inclinado; capacidade de até 5000 kg/h.

- Proteção de Segurança – Sistema de proteção contra sobrecarga e térmica embutido para evitar entupimentos ou emaranhamentos de material.

- Fácil Manutenção – Estrutura de lâmina modular para substituição rápida e redução do tempo de inatividade.

Parâmetros da Máquina de Corte de Tecido à Venda

As seguintes são algumas especificações de máquinas de corte de resíduos têxteis que estão a vender bem. Também podemos fornecer cortadores de têxteis personalizados com base nas suas necessidades de produção.

| Modelo | 500B | 800C | 1200B | 1600B | 2400B |

| Capacidade (kg/h) | 300-500 | 500-800 | 800-1200 | 1000-3000 | 2000-5000 |

| Potência do Motor (KW) | 5.5+1.5 | 7.5 + 1.5 | 15 + 2.2 | 18.5 + 3.0 | 22 + 3.0 |

| Comprimento de Corte (mm) | 5-150 | 5-150 | 5-150 | 5-300 | 10-300 |

| Espessura de Corte (mm) | 20 | 30-50 | 30-50 | 30-150 | 30-200 |

| Tamanho da Correia de Entrada/Saída (mm) | 2800*350 | 2800*350 | 3000*520 | 3000*720 | 3000*1100 |

| Dimensões (mm) | 3200*1000*1200 | 3200*1000*1200 | 7000*1500*1500 | 7000*1800*1950 | 5800*2200*1950 |

Princípio de Funcionamento da Máquina de Corte de Fibra de Tecido

- Alimentação:

Os resíduos têxteis são alimentados na entrada por um transportador. - Corte Rotativo:

As lâminas rotativas trabalham contra lâminas fixas dentro da câmara para cortar materiais fibrosos em pedaços curtos. - Descarregamento:

Os pedaços de tecido cortados são descarregados através de uma saída para processamento adicional. - Configurações Ajustáveis:

A velocidade, a folga da lâmina e o comprimento da saída podem ser ajustados para diferentes materiais e objetivos de processamento.

O design do cortador rotativo inclinado garante um corte contínuo sem entupimentos.

Obtenha Sua Solução Personalizada de Reciclagem de Fibra

Procurando uma forma eficiente de processar resíduos têxteis? As nossas máquinas de corte de resíduos de tecido são confiáveis em plantas de reciclagem em vários países. Contacte-nos hoje para um orçamento e uma solução de corte gratuita!

Perguntas Frequentes Sobre a Máquina de Corte de Resíduos de Tecido

Se você ainda tiver outras perguntas, sinta-se à vontade para nos contatar. Estamos aqui para ajudar!

Pode lidar com materiais espessos, como sobreposições de couro?

Suporta camadas ultra-grossas de 20-200mm

O tamanho de corte pode ser ajustado?

Sim. Oferecemos configurações personalizadas de 5 mm a 300 mm de comprimento de saída.

A máquina é segura para os operadores?

Sim. A máquina inclui capas de segurança, um botão de emergência e sensores de proteção.

Como manter a máquina de corte de fibra?

Limpe regularmente a poeira de fibra, lubrifique os rolamentos e verifique a afiação da lâmina a cada 300 horas.

Você fornece suporte para instalação ou operação?

Sim. Oferecemos instalação no local, orientação técnica, fornecimento de peças sobressalentes, entre outros.