Автоматический завод по переработке резины для эффективной переработки шин

| Имя | Полностью автоматическая линия по переработке шин |

| Сырье | Шины диаметром менее 1200 мм, включая автомобильные шины, шины для автобусов, шины для грузовиков и т.д. |

| Конечные продукты | Резиновая порошковая фракция 10-40 меш, или регулируемые резиновые гранулы, блоки |

| Емкость | Индивидуальные |

| Гарантия | Годовая гарантия бесплатно |

| Услуги | Техническая поддержка и установка на месте. |

Теперь вы можете уточнить технические подробности у наших менеджеров проектов.

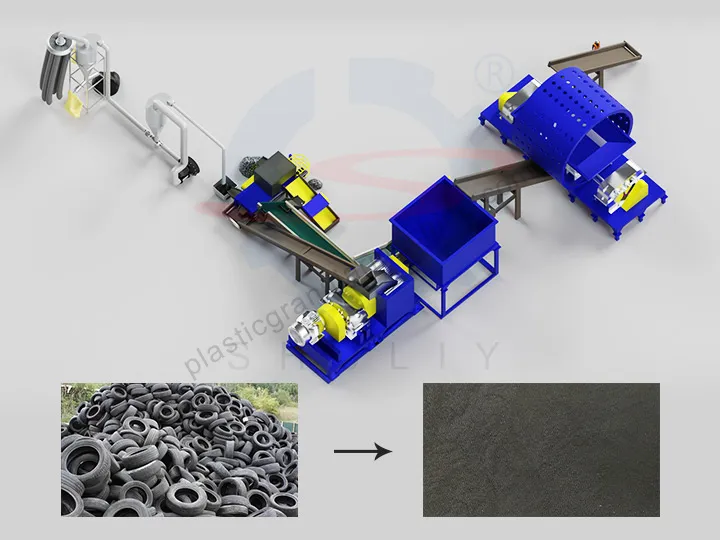

Наш полностью автоматизированный завод по переработке резины предназначен для преобразования отработанных шин в резиновые блоки, гранулы или порошок для переработки. Оборудование эффективно, простое в эксплуатации и может помочь вам начать или улучшить ваш бизнес по переработке шин!

Применение полностью автоматической линии по переработке шин

Наш полностью автоматизированный завод по переработке резины предназначен для шин диаметром до 1200 мм, включая автомобильные, автобусные, грузовые и другие шины. Благодаря интегрированной предварительной обработке, измельчению, шлифованию, а также магнитному и волокнистому разделению, он эффективно производит высококачественный резиновый порошок (10-40 меш) с чистотой более 99%. Выход продукции полностью соответствует требованиям отрасли для модифицированного асфальта, легкоатлетических дорожек, переработанных резинок и многого другого!

Мы можем предоставить индивидуальные решения по переработке для переработчиков шин, производителей шин, производителей переработанной резины, станций по переработке отходов и т.д.

Ключевые особенности нашей линии по производству резиновой пудры

- Доступны три гибкие конфигурации для удовлетворения различных потребностей в переработке шин.

- Резиновый порошок различной тонкости (10-40 меш) может быть изготовлен по индивидуальному заказу.

- Ключевые части изготовлены из сплавов и других износостойких материалов, могут быть предоставлены сертификаты CE и ISO.

- Классифицированная переработка резины, стальной проволоки, нейлона и т.д., с чистотой более 99% резинового порошка.

- Полностью автоматическая работа, более безопасная и эффективная, с максимальной эффективностью переработки резины до 2300 кг/ч.

Три популярных решения по переработке шин для различных нужд

Процесс производства резиновой порошка состоит из: предварительной обработки, измельчения шин, фрезерования шин и сортировки. В зависимости от типа шины или мощности измельчителя шин могут быть выбраны различные методы предварительной обработки.

Завод по переработке шин 1

Если шины меньше или мощнее, их не нужно предварительно обрабатывать, и их можно перерабатывать непосредственно через шредер для шин и системы измельчения и сортировки шин (мельницы, магнитные сепараторы, сортировщики нейлона).

Завод по переработке резины 2

- Удалитель стальных проволок из старых шин

- Машина для резки шин разрезает бракованные шины на 2-3 части.

- Шредер для шин измельчает резину на блоки размером 50-100 мм.

- Измельчение и сортировка с системой производства резинового порошка.

Линия по производству крошки резины 3

- Удалите борт шины, который содержит множество стальных проволок, и нарежьте бракованные шины для облегчения измельчения.

- Используйте разделитель проволоки для отделения стальных проволок от резины.

- Измельчите резину из шагов 1 и 2 на блоки размером 50-100 мм.

- Мельница и экран для премиум порошков из шин.

Детали машин для переработки шин

Снятие корки с шин

Наша гидравлическая машина для протяжки проволоки шин использует высокое гидравлическое давление для надежного захвата и извлечения стальных проволок из шин, обеспечивая эффективное разделение и защиту последующего оборудования для измельчения. Это первый шаг в Завод по переработке резины 2.

- Тип: одно крючковый / двойной крючковый снятие покрышек.

- Производительность: 20-30 / 40-50 шт. в час.

- Мощность: 11 / 18.5 кВт.

- Применение: шины 900-1200 мм.

Резак для шин

Сделанная из лезвий Cr12MoV, машина для резки шин является прочной и износостойкой, эффективно нарезает безободковые шины до 1200 мм на резиновые блоки до 900 мм.

- Производительность: 60 шт/ч

- Вход: шины 900-1200 мм

- Выход: блоки шин <900 мм

- Мощность: 7.5 кВт

- Материал лезвия: Cr12MoV

Машина для резки и удаления бортов шин

Интеграция функций удаления бусин и резки в одном устройстве сокращает время переноса материала и делает процесс более безопасным и эффективным. Это первый шаг в предварительной обработке Линия по переработке шин 3.

- Производительность: 3 т/ч

- Мощность: 7.5+3 кВт

- Вход: шины 900-1200 мм

- Выход: <900 мм шины

Сепаратор стальной проволоки шин

Машина для разделения стальной проволоки от шин, изготовленная из прочных материалов, эффективно отделяет резину от стальной проволоки с помощью механического разрыва и прокатки. Обычно она расположена после машины для удаления бортов шин и резки. Решение по переработке шин 3, это повышает чистоту резинового порошка и защищает оборудование downstream.

- Производительность: 120 шт/ч

- Мощность: 18.5 кВт

- Вес: 1800 кг

- Размер машины: 2*1.9*1.8м

Шредер для шин

Шредер для шин на продажу широко используется на заводах по переработке резины для обработки предварительно обработанных шин в однородные резиновые кусочки размером от 5 до 100 мм. Он подходит для небольших легковых шин, <900 мм шинных блоков и демонтированных OTR (внедорожных) шин.

Шредер для шин предлагает регулируемый размер частиц, высокую мощность и производительность с прочной конструкцией для непрерывной высокоэффективной работы. Ключевые компоненты, такие как экран и лезвия, легко разбираются для обслуживания.

| Модель | 900 | 1000 | 1200 | 1500 | 1800 |

| Производительность (т/ч) | 2 | 4 | 5-6 | 8-10 | 15-20 |

| Мощность (КВт) | 64.5 | 94.5 | 157 | 188.5 | 328.5 |

| Размер входа (мм) | <900 | <1000 | <1200 | <1200 | <1400 |

| Размер выхода (мм) | 50 | 60 | 60 | 75 | 100 |

| Толщина лезвия (мм) | 50 | 60 | 60 | 75 | 100 |

| Количество лезвий | 16 | 16 | 18 | 20 | 18 |

Мельница для шин и магнитный сепаратор

Система шлифовки и сортировки шин включает в себя прецизионный шлифовальный станок для шин и двухступенчатые магнитные сепараторы. Она эффективно измельчает резиновые частицы размером от 30 до 100 мм в мелкий порошок 10-40 сетки, одновременно удаляя железные примеси, достигая чистоты 99% для оптимального повторного использования. Конкретные мощности различных моделей следующие.

| Размер выходного продукта\Модель | Линия SL-350 | Линия SL-400 | Линия SL-450 | Линия SL-560 | Линия SL-560 D | Линия SL-660 |

| 10 ячеек | 250-300 | 400-500 | 500-600 | 900-1000 | 1500-1600 | 2100-2300 |

| 20 ячеек | 180-230 | 300-350 | 400-500 | 600-700 | 1200-1300 | 1600-1700 |

| 30 сетка | 150-210 | 240-280 | 350-450 | 450-550 | 1000-1100 | 1200-1300 |

| 40 сетка | 80-120 | 150-175 | 200-250 | 300-350 | 800-900 | 900-1000 |

Машина для сортировки волокна

Фибровый сепаратор использует сортировку по воздуху и различия в плотности для эффективного отделения тонких волокон от резиновой пудры, повышая ее чистоту. С регулируемой скоростью ветра и энергоэффективной работой это оборудование идеально подходит для переработки резины и других химических отраслей для отделения и классификации мелких частиц.

- Производительность: 800-1000 кг/ч

- Скорость двигателя: 760 об/мин

- Мощность двигателя: 5.5 кВт

- Размер машины: 1500*1500*3400мм

Профессиональные машины для переработки шин на продажу

Наши полностью автоматизированные заводы по переработке резины имеют модульную конструкцию, что позволяет гибко настраивать оборудование. Они эффективно производят резиновые блоки, гранулы или порошки с регулируемыми размерами частиц для различных отраслевых применений. Пожалуйста, не стесняйтесь обращаться к нам, чтобы найти подходящее решение для переработки шин!