通过蛋托生产线最大化收益

| 姓名 | 蛋托生产线 |

| 原料 | 各种废纸 |

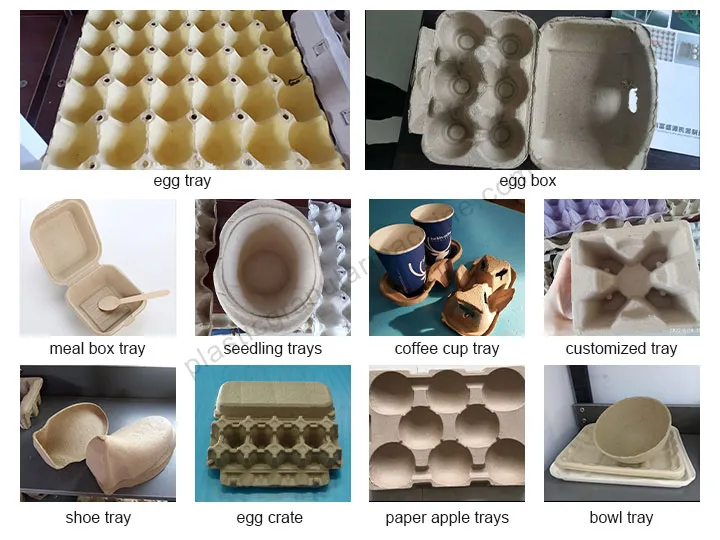

| 最终产品 | 各种纸托盘,如蛋托、鞋托、苹果托等。 |

| 容量 | 1000-7000 件/小时 |

| 服务 | 现场安装和操作指南 |

| 保修单 | 一年免费 |

您现在可以向我们的项目经理询问技术细节

我们的纸浆蛋托生产线每小时的产能为1000到7000个。它可以高效地将废纸转化为各种纸托产品,如蛋托、苹果托、鞋托、咖啡杯托等。这些产品广泛应用于食品、农业和日常必需品等多个领域。

使用我们的设备,每个蛋托的平均总成本仅为0.026美元至0.04美元,而国际市场价格通常为0.07美元至0.10美元或更高。利润率高达150%-250%,这使得该项目成为一个非常有吸引力的投资项目!

蛋托机的原材料和成品

我们的蛋托生产线使用废纸和植物纤维,如旧报纸、纸箱、使用过的蛋托、木浆等作为原材料。通过制浆、成型、干燥和包装,生产出透气、可生物降解、环保的蛋托。

此外,通过更换模具和调整生产工艺,我们可以生产各种尺寸、形状和颜色的高质量纸托,以满足不同的需求。我们的托盘广泛用于食品包装、日常用品、运输、电子防震包装等。

我们的蛋托生产线的核心特点

- 用于回收废纸的原材料广泛可得。

- 成品蛋托可以在性能、颜色、厚度和形状上进行定制。

- 可生物降解的蛋盒符合环境标准,并且透气。

- 该机器提供自动或半自动操作。

- 各种干燥方法适应不同的气候。

- 低生产成本带来高回报,利润率为150%-250%。

- 我们提供产能为1,000–7,000个/小时的生产线,并支持整个规划过程,包括安装和免费保修。

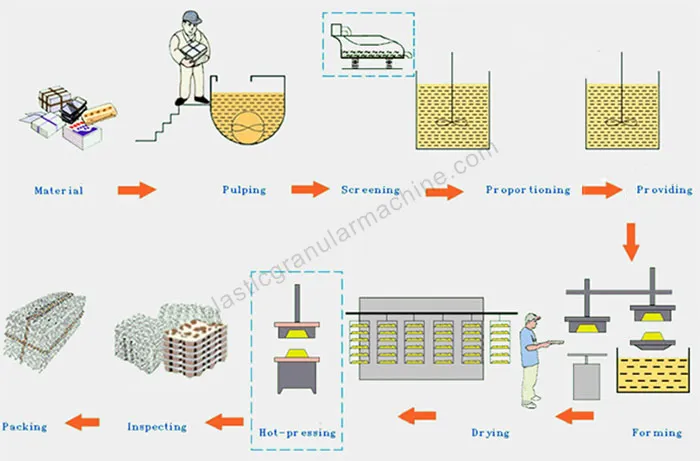

完整的蛋托制造过程揭晓

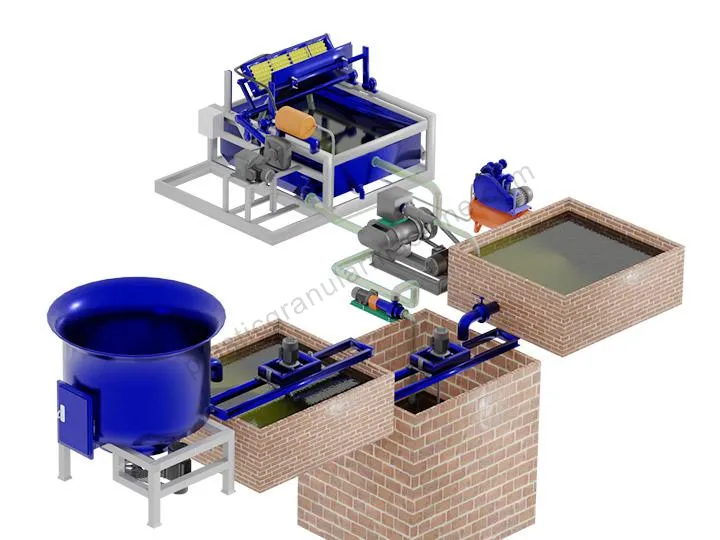

纸浆处理

- 将废纸和水放入液压打浆机中以粉碎浆料。

- 然后,添加剂被加入到浆料调理罐中以修改浆料。持续搅拌以形成均匀的浆料。

- 浆料泵将浆料输送到供料罐。

- 加入水以将浆料稀释到3-5%的浓度。

蛋托成型

成型过程是鸡蛋托生产线中最重要的环节。我们提供多种型号的鸡蛋托成型机,包括单面、四面和八面鸡蛋托成型机,产能从每小时 1,000 件到 7,000 件不等。

- 蛋托成型机的模具在真空泵的作用下吸附浆料。

- 多余的水通过不锈钢网从浆料中排出,流入回收池以便重复使用。

- 经过真空脱水,蛋托成型。

- 真空机随后帮助脱模蛋托并将其转移到输送带上。

干燥

初步成型的湿蛋托必须干燥,以增加其稳定性和坚固性。根据当地气候、场地和其他条件选择最合适的干燥方法。我们的蛋托生产线支持以下几种方法:

- 手动干燥

- 烘干炉烘烤

- 多层金属干燥。

- 土木工程干燥。

热压与包装:

- 热压成型机在高温下压制蛋托,以提高其强度和外观。

- 堆垛机根据数据整齐地堆放热压蛋托,提高计数和包装效率。

- 打包机将蛋托夹住并打包,便于运输和存储。

选择我们以获得高回报的蛋托制造厂

我们的蛋托生产线投资少但回报高,已销售到包括沙特阿拉伯、尼日尔、马里、西班牙、瑞士等多个国家,并获得了良好的反馈。

如果您对我们的产品感兴趣,请随时与我们联系以获取定制解决方案!