半自动轮胎回收生产线

| 姓名 | 半自动轮胎回收生产线 |

| 原料 | ≤1200毫米轮胎 |

| 最终产品 | 10-40目(0.63-2.5毫米)橡胶粉 |

| 容量 | 定制 |

| 保修单 | 一年免费 |

| 服务 | 技术支持和现场安装。 |

您现在可以向我们的项目经理询问技术细节

半自动轮胎回收生产线结合了人工辅助和自动化设备的协同操作,以经济高效的方式将废旧轮胎转化为橡胶粉。

它可以广泛用于回收常见的废旧轮胎,如汽车轮胎,并且只需2-4人即可操作,这使得它特别适合预算有限的初创企业或小型到中型轮胎回收厂。

轮胎回收生产线的应用和最终产品

半自动轮胎回收生产线适用于处理直径≤1200mm的各种废旧轮胎,如汽车轮胎、卡车轮胎等。

通过预处理、 shredding、 grinding 和筛分的过程,废旧轮胎被加工成 10-40 目可调的橡胶颗粒或粉末,产品的纯度高达 99% 或更高。

废旧轮胎回收生产线的主要特点

- 低投资: 结构简单,操作灵活,采购成本低,适合初创企业或小型工厂。

- 高回报: 高效率,产品质量好,纯度高达99%,在市场上竞争力强。

- 操作简单: 只需2-4人即可完成生产。设备配备安全防护装置,操作安全。

- 环境保护: 可提供CE和ISO证书,能耗低,无污染,符合环保标准。

半自动橡胶粉生产线是如何工作的?

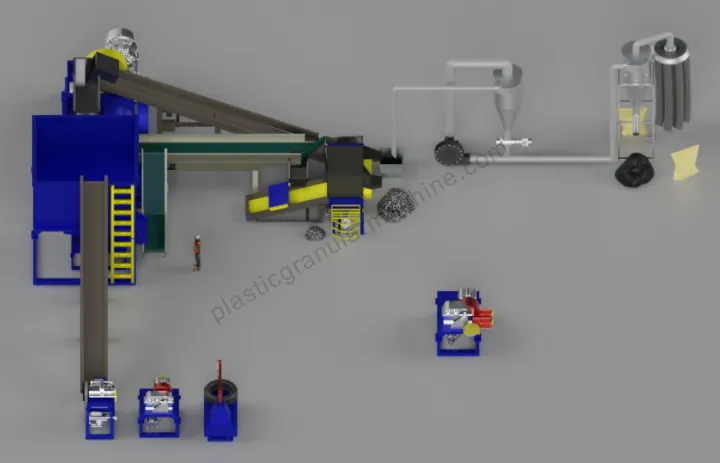

完整的半自动废轮胎回收生产线包括轮胎侧壁切割机、轮胎条切割机、轮胎块切割机、轮胎撕碎机、橡胶粉碎机、磁选系统和纤维分离器。

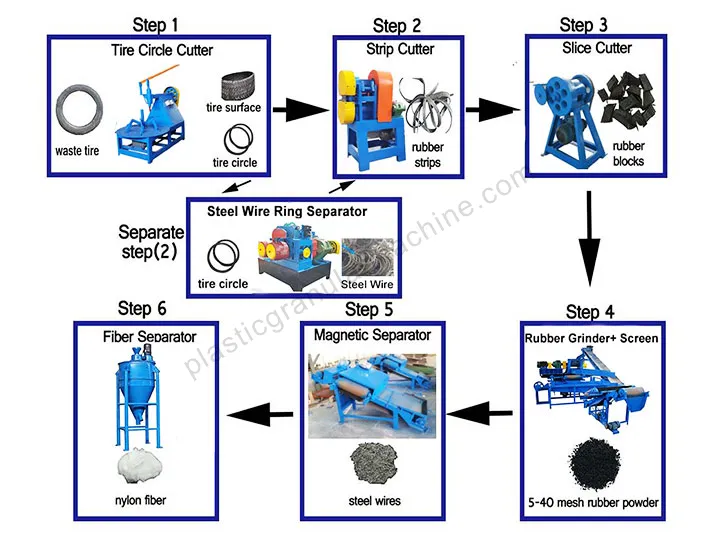

- 预处理 1使用轮胎环切割机,切割掉含有大量钢丝的轮胎胎圈,以获得橡胶轮胎侧壁。

- 预处理 2: 利用轮胎条切割机将轮胎侧壁切割成3-5厘米宽的条状。

- 预处理 3: 然后,用轮胎块切割机将橡胶条切割成5厘米长和宽的小块,以便进行后续的粉碎过程。

- 研磨与筛分: 双辊高效地通过剪切和摩擦将橡胶块研磨成10-40目粉末。振动筛和多级筛分系统自动分离合格粉末,回收任何不符合尺寸要求的材料。

- 磁分离: 通过磁辊吸附,混合在橡胶粉中的铁丝被有效去除,橡胶粉的纯度得以提高。

- 纤维分离: 通过气流筛选去除残留的尼龙纤维,以确保橡胶粉的纯度超过99%。

高效的轮胎回收机器出售

我们的轮胎回收生产线是模块化和灵活的。以下是每台机器的主要规格信息。

轮胎侧壁切割机

高效去除钢丝,保护并延长整个生产线的使用寿命。

- 处理能力:40件/小时

- 电机功率:4+0.75千瓦

- 工作范围:650-1250毫米轮胎

- 机器尺寸:1.8米*1.3米*1.6米

轮胎条切割机

强大的切割力,操作简单,占地面积小。

- 容量:1000公斤/小时

- 电机功率:5.5 KW

- 电机转速:45转/分钟

- 最终产品:3-5厘米宽的条

轮胎块切割机

稳定的切割有效提高轮胎回收效率,保护后续设备,适合连续操作。

- 型号:QKJ-358,更新的轮胎块切割机

- 产能:800/1500 kg/h

- 电机功率:5.5/18.5 KW

轮胎磨碎机和磁选机

精细磨粉,多级筛分,均匀细腻的材料,尺寸可调,纯度大于99%。

- 型号:SL-350/400/450/560/560D/660 线

- 产能:80-300 / 150-400 / 200-600 / 300-1000 / 800-1600 / 900-2300 kg/h

- 输出尺寸:10-40 目(2.5-0.63 毫米)

纤维分离器

高效去除尼龙纤维,不损害橡胶粉,节能环保。

- 产能:800-1000 kg/h

- 电机功率:5.5 KW

- 输出纯度:超过99%

获取定制的轮胎回收解决方案!

无论您是刚开始轮胎回收业务,还是已经在运营成熟的回收工厂,我们都提供针对各种类型轮胎的定制解决方案——从半自动到全自动轮胎回收生产线。如需更多详细信息,请随时与我们联系!