Redresseur de barres pour le traitement des barres d'acier

| Nom | Redresseur de barres d’armature |

| Matières premières | Barres métalliques recyclées de 6 à 25 mm |

| Sortir | Barres d’acier droites de 500 à 2000 mm |

| Moteur | 4-15 kW |

| Nos prestations | Fournir la conception de solutions, l’installation sur site, l’assistance technique, et plus encore. |

| garantie | Un an gratuit |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

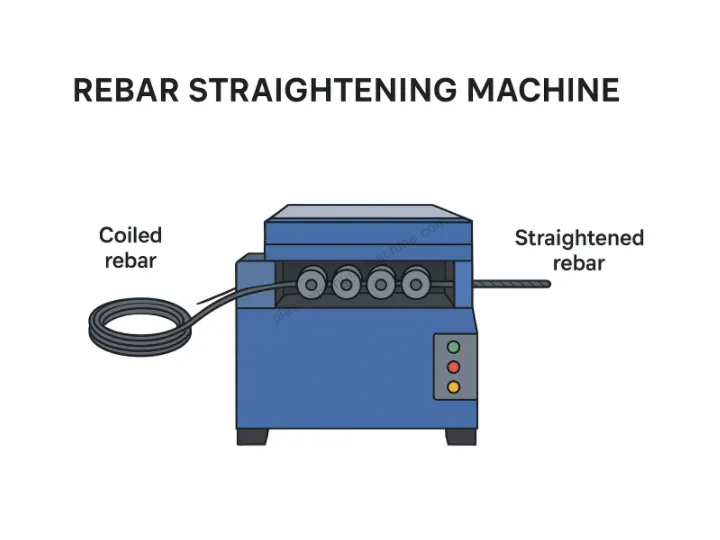

Le redresseur de barres d’armature est une machine essentielle dans les industries de la construction et de la transformation de l’acier. Il est principalement utilisé pour redresser et transformer des barres enroulées ou pliées en longueurs droites et uniformes pour une coupe, une soudure ou une utilisation en construction ultérieure. Que vous travailliez avec de petites diamètres ou de lourdes tiges en acier, une machine de redressage garantit une haute précision, une opération rapide et une qualité de produit constante.

Pourquoi vous avez besoin d’une machine de redressage de barres d’armature

Dans la construction moderne et la fabrication de l’acier, la précision et l’efficacité sont essentielles. Les rebars enroulés ou pliés ne peuvent pas être utilisés directement pour le renforcement ; ils doivent être redressés au préalable.

C’est là qu’intervient un redresseur de barres — il transforme des bobines enchevêtrées en barres d’acier parfaitement droites, prêtes à l’emploi. Choisir une machine fiable de redressage assure un fonctionnement plus fluide, une qualité constante et des coûts de main-d’œuvre réduits.

Matériaux bruts & produits finis de notre redresseur de barres d’armature

La machine de redressage de barres en acier est conçue pour traiter diverses matières premières telles que :

- Rebards enroulés (6-25 mm)

- Tiges en acier déformées ou pliées

- Barres métalliques rondes et fils

Après le redressement, les produits finis présentent :

- Surface lisse, uniforme, sans déformation

- Longueur de coupe précise (couramment 500-2000 mm)

- Prêtes pour la soudure, la construction ou le retraitement

Ces barres finies sont idéales pour le béton armé, la production d’acier structural, et l’industrie manufacturière.

Comment fonctionne le redresseur de barres

À l’intérieur de la machine de redressage de barres, l’acier passe à travers un ensemble de rouleaux précisément disposés qui tournent à grande vitesse.

Chaque barre est corrigée plusieurs fois (typiquement 5-6 trous, 20 passes par cycle) pour éliminer les torsions et les courbes.

La machine de redressement de barre alimente ensuite automatiquement la barre dans une unité de coupe, où elle est coupée à la longueur prédéfinie.

Le processus est entièrement automatique — combinant redressement, mesure et coupe en une seule opération continue. Cela améliore non seulement la précision, mais aussi la productivité pour les lignes de traitement de l’acier.

Plusieurs modèles de machines de redressage de barres disponibles

Notre machine de redressage de bobines d’armature propose plusieurs modèles pour s’adapter à différentes diamètres de barres et besoins de production. Nous pouvons également fournir des redresseurs personnalisés selon vos besoins. (N’hésitez pas à nous contacter)

| Modèle | Diamètre de redressement (mm) | Trous de redressement | Longueur de coupe (mm) | Puissance du moteur (kW) | Poids de la machine (kg) | Machine Dimension (mm) |

|---|---|---|---|---|---|---|

| ET-6-10 | 6-10 | 5 trous*20 passages | 500-2000 | 4 | 570 | 1100*720*1150 |

| ET-6-14 | 6-14 | 5 trous*20 passages | 500-2000 | 5 | 730 | 1200*790*1220 |

| ET-8-16 | 8-16 | 5 trous*20 passages | 500-2000 | 5 | 750 | 1250*820*1300 |

| ET-14-25 | 14-25 | 6 trous*20 passages | 500-2000 | 15 | 980 | 1550*890*1600 |

Configurations personnalisées disponibles pour des diamètres plus grands ou des matériaux en acier spécifiques.

Pourquoi la qualité est importante — Bon vs Mauvais machines de redressage

Toutes les machines de redressage de barres ne se valent pas.

Les machines de mauvaise qualité conduisent souvent à des résultats pliés, des surfaces rugueuses, des arrêts fréquents, et des coupes imprécises — gaspillant des matières premières et augmentant les coûts de maintenance. En revanche, une machine de redressement de tiges en acier de haute qualité offre :

- Barres parfaitement droites avec des surfaces propres et lisses

- Longueur de coupe cohérente avec peu de déchets

- Fonctionnement stable et longue durée de vie

- Vitesse de travail élevée et rouleaux de précision

C’est pourquoi les constructeurs professionnels et les transformateurs d’acier choisissent notre redresseur de barres d’armature hydraulique — conçu avec des rouleaux durables, des cadres robustes et des systèmes de contrôle de précision.

Notre engagement en matière de qualité et de service

Chez EFFICIENT, nous concevons chaque machine de redressement de barre en métal pour la performance et la fiabilité.

Nous promettons :

- Fonctionnement stable et qualité testée avant livraison

- Solutions sur mesure pour vos tailles de barres en acier et besoins de production

- Expédition rapide dans le monde entier et documentation complète

- Guidance technique & support pièces détachées

Notre objectif est d’aider nos clients à atteindre une efficacité accrue, une meilleure qualité et une fiabilité à long terme.

Applications typiques de la machine de redressage de barres en acier

La machine de redressage de barres rondes est largement utilisée dans :

- Usines de construction et de traitement de l’armature

- Ateliers de fabrication d’acier

- Lignes de production de béton préfabriqué

- Centres de recyclage de métaux de rebut

Idéal pour redresser l’acier doux, l’armature déformée, les barres rondes et les tiges métalliques.

Conclusion

Un redresseur de barres d’armature est un investissement essentiel pour toute entreprise sidérurgique ou de construction. Avec une machine de redressement hydraulique, vous pouvez produire des barres uniformes, précises et lisses — plus rapidement et à moindre coût.

N’hésitez pas à nous contacter. Choisissez notre redresseur de barres en acier pour une performance durable et un support professionnel !