Машина для полировки металла для переработки измельченного металлолома

In the competitive scrap recycling industry, purity is profit. While shredders break metal down, they often leave behind fragments covered in rust, oxidation, or stubborn oil. EFFICIENT Machinery provides the specialized metal polishing machine—the “last mile” solution for your recycling line. Designed for high-volume processing of shredded fragments, this drum-type dry grinding mill transforms dull, low-value scrap into high-purity, bright metal products that command top market prices.

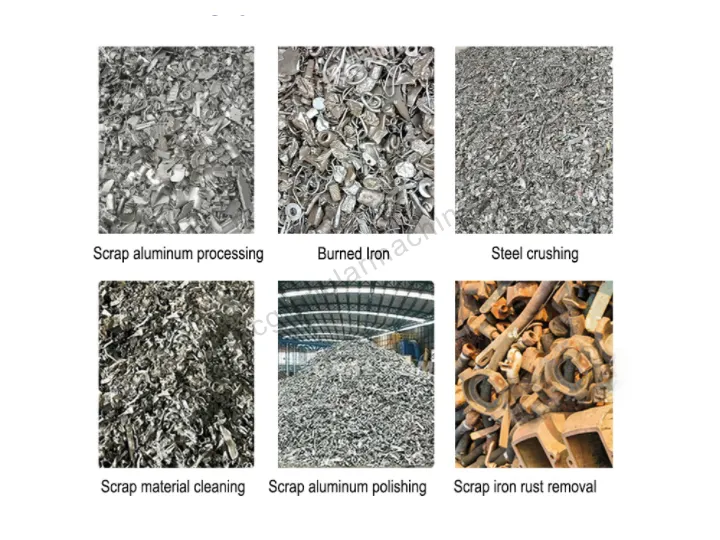

Application: The Final Touch in the Recycling Line

Our metal polishing machine is specifically engineered for the final stage of metal crushing and recycling lines. It doesn’t just clean; it refines.

- Post-Shredding Enrichment: Ideal for processing shredded burnt iron, copper fragments, and aluminum chips.

- Surface Preparation: Perfect for removing the “oxidation layer” from power plant-burnt iron.

- Industry Versatility: Widely used in non-ferrous metal recycling, automotive scrap processing, and small hardware finishing.

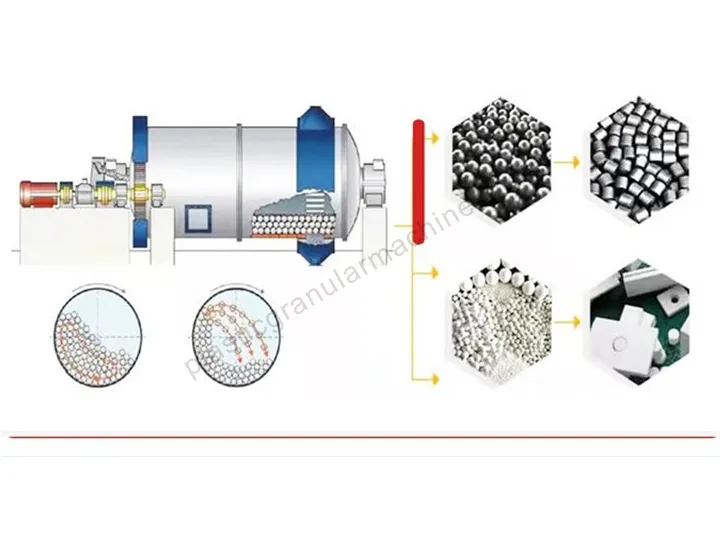

How It Works: The Science of Friction

This metal polishing machine utilizes a sophisticated dry-grinding principle.

- Кормление: Shredded fragments (under 400mm) enter the extra-large hopper.

- Centrifugal Tumbling: A high-torque motor drives the drum. Inside, specialized guide plates and turbulence-dissipating plates force a continuous, multi-dimensional collision between the metal fragments and the abrasive ore/media.

- Absorption & Friction: As the drum rotates, the media absorbs oil stains and grinds away rust through intense friction.

- Refinement: The process improves surface roughness by 1-2 grades without altering the original dimensional accuracy of the parts.

Why Choose EFFICIENT’s Polishing Solutions?

We don’t just build machines; we build reliability. Our metal polishing machine stands out through its heavy-duty construction:

- Aperture Gear Excellence: Unlike welded alternatives, our gears are made of high-strength alloy with one-piece casting. This ensures rock-solid stability and a longer service life under 24/7 operation.

- Wear-Resistant Body: The drum is fabricated from extra-thick steel plates with high-tech welding. It’s built to withstand the constant impact of sharp metal fragments.

- Uniform Output: The enlarged hopper design ensures a consistent feed rate, preventing the uneven production common in smaller units.

- Deformation-Free Finishing: It is particularly suitable for easily deformable workpieces, providing a bright finish while maintaining structural integrity.

Raw Materials & Results: The Visual Proof

- Input: Oily scrap copper, rusty, burnt iron from power plants, oxidized aluminum fragments, and jagged, shredded steel.

- Output: Degreased, rust-free, deburred, and brightened metal fragments ready for immediate smelting or resale

Technical Specifications: The Hard Data

| Model Component | Specifications / Features |

|---|---|

| Primary Keyword | Metal Polishing Machine / Dry Grinding Mill |

| Material Capability | Burnt Iron, Copper/Aluminum Chips, Non-ferrous Metals |

| Processing Diameter | < 400 mm |

| Core Structure | One-piece Alloy Casting Gear |

| Материал корпуса | Reinforced Heavy-Duty Steel Plate |

| Finishing Effect | Surface Roughness Improvement (1-2 Grades) |

Maintenance & After-Sales Support

We understand that maintenance shouldn’t stop production.

- Easy-Access Points: All lubrication points are externally accessible.

- Modular Lining: The internal plates are replaceable, extending the total lifespan of the drum indefinitely.

- Global Support: EFFICIENT provides 24-hour technical consultation and rapid spare parts shipping to ensure your line never goes cold.

Boost Your Purity Today

Stop selling “dirty” scrap for less. Enhance your material value with the EFFICIENT metal polishing machine or metal recycling plant. Whether you are dealing with burnt iron or complex non-ferrous fragments, our technology delivers the finish your customers demand.