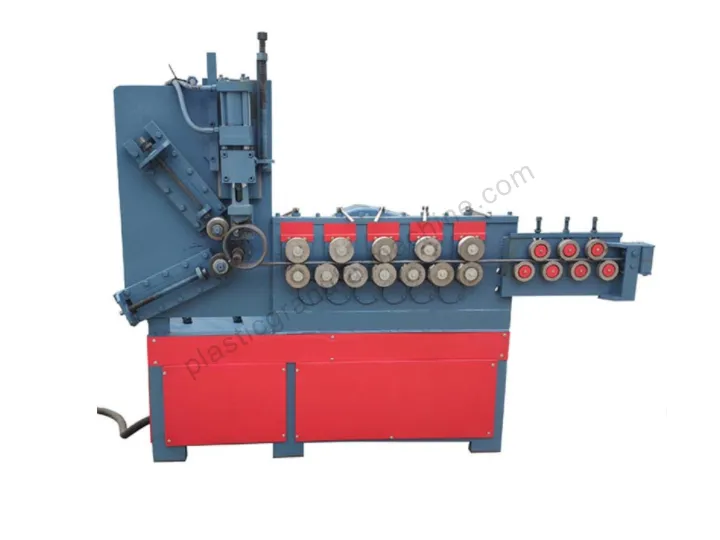

Máquina para fabricar anillos de refuerzo

| Nombre | máquina de fabricación de anillos de refuerzo |

| Entrada | Varillas de 3-25 mm de diámetro |

| Producción | Anillos de 50-3000 mm de diámetro |

| Velocidad | 16-30 m/min |

| Modo de operación | Automático |

| Servicios | Soporte técnico e instalación en sitio. |

| Garantía | Un año gratis |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

La máquina de fabricación de anillos de refuerzo es una solución automática avanzada para formar barras de acero en formas circulares o en espiral precisas. Diseñada para proyectos como ferrocarriles de alta velocidad, puentes, metro y cimientos fotovoltaicos, esta máquina garantiza una producción rápida, tamaños de anillo uniformes y calidad constante — todo con mínimo trabajo manual.

¿Qué es la máquina de fabricación de anillos de refuerzo?

Nuestra máquina de fabricación de anillos de refuerzo combina tecnología de control CNC con un sistema de transmisión hidráulica para lograr una operación totalmente automática.

Desde la alimentación y enderezado hasta la formación y corte del anillo, todos los pasos se completan en un ciclo continuo. Los operadores simplemente configuran los parámetros necesarios, y la máquina procesa automáticamente un paquete completo de barras de acero con un rendimiento estable y resultados precisos.

En comparación con el doblado manual, reduce la intensidad laboral, elimina errores dimensionales y aumenta la productividad varias veces.

¿Cómo funciona la dobladora de círculos de refuerzo?

La máquina de fabricación de anillos de varillas de refuerzo consta de varios componentes clave:

- Motor eléctrico y sistema hidráulico (incluyendo bomba de aceite, motor, válvulas y depósito de aceite)

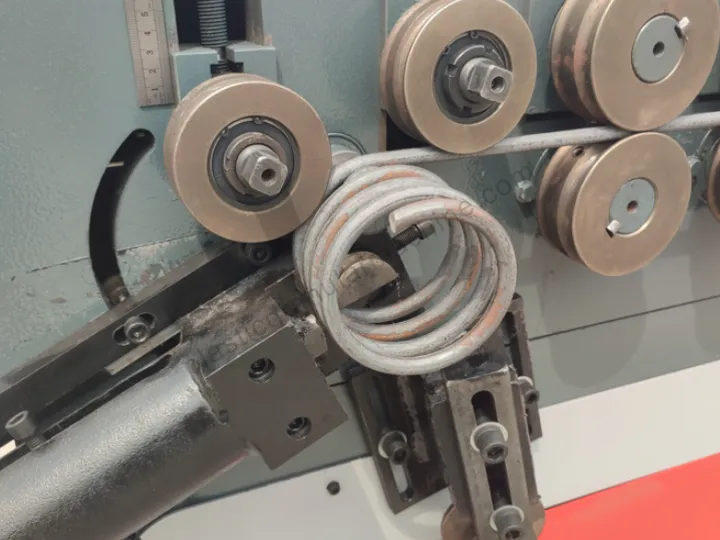

- Caja de engranajes de enderezado y ruedas de preajuste

- Conjuntos de redondeo y corte

- Sistema de control CNC PLC con interfaz de pantalla táctil

- Dispositivos de conteo automático y seguridad

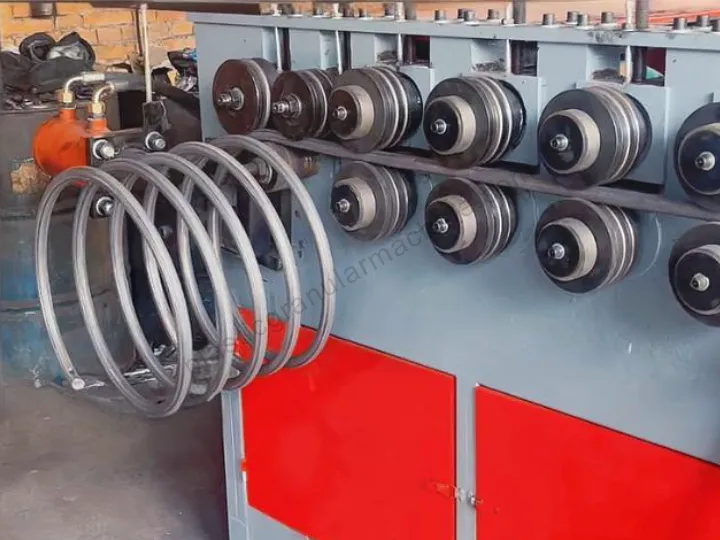

Bajo el control del sistema PLC, el motor impulsa la bomba de aceite para iniciar el movimiento hidráulico. El motor hidráulico luego alimenta la caja de engranajes de enderezado, que alimenta continuamente la barra de acero hacia adelante. Cuando la barra entra en el conjunto de redondeo, se dobla en una forma circular precisa. Finalmente, el cilindro de corte corta automáticamente la barra a la longitud preestablecida, completando un ciclo completo.

Este proceso coordinado — desde la alimentación hasta el corte — es completamente automatizado, garantizando un funcionamiento suave, alta eficiencia y precisión constante en los anillos dentro de ±0.2 mm.

Parámetros técnicos de varias dobladoras de anillos de refuerzo

| Modelo | Diámetro de la barra (mm) | Diámetro del anillo (mm) | Potencia del motor (kW) | Velocidad (m/min) | Precisión | Peso (kg) |

|---|---|---|---|---|---|---|

| ET-3-6 | 3-6 | 50-1000 | 4 | 16-25 | ±0.2 mm | 480 |

| ET-6-10 | 6-10 | 50-800 | 5.5 | 16-25 | ±0.2 mm | 560 |

| ET-8-12 | 8-12 | 50-1500 | 7 | 16-25 | ±0.2 mm | 640 |

| ET-10-14 | 10-14 | 50-1800 | 7 | 16-25 | ±0.2 mm | 690 |

| ET-16-20 | 16-20 | 50-2200 | 11 | 16-30 | ±0.2 mm | 1150 |

| ET-22-25 | 22-25 | 50-3000 | 15 | 16-30 | ±0.2 mm | 1350 |

¿Por qué elegir nuestra máquina de fabricación de anillos de refuerzo?

Usar una máquina de fabricación de anillos de refuerzo trae ventajas claras sobre el doblado manual:

- Mayor eficiencia: El alimentador, doblador y cortador automáticos aumentan la producción en 3-5 veces en comparación con el trabajo manual.

- Formación precisa: El control CNC mantiene cada tamaño de anillo consistente, con una precisión de hasta ±0,2 mm.

- Ahorro de mano de obra: Un operador puede manejar todo el sistema a través de una interfaz de pantalla táctil.

- Rendimiento estable: La transmisión hidráulica y los rodillos de aleación garantizan un funcionamiento suave y una larga vida útil.

- Ahorro de material: El corte automático reduce el desperdicio y mejora el rendimiento.

- Uso versátil: Adecuado para producir anillos de varilla de refuerzo circulares y en espiral para puentes, túneles y proyectos de cimentación.

- Fácil mantenimiento: Estructura sencilla, componentes duraderos y bajo coste operativo.

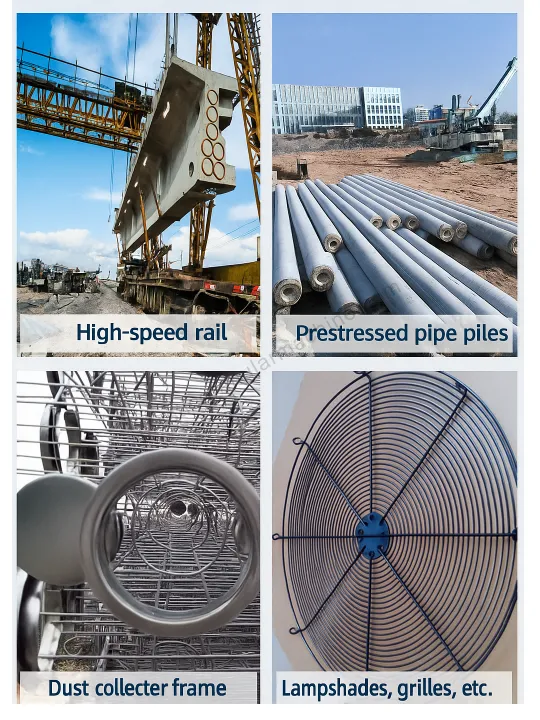

Aplicaciones de la máquina de fabricación de anillos de refuerzo

Nuestra máquina de fabricación de anillos de refuerzo puede aplicarse en las siguientes áreas:

- Refuerzo de ferrocarril de alta velocidad y puentes

- Construcción de túneles de metro

- Anclajes de cimientos fotovoltaicos

- Producción de pilotes de concreto prefabricado

- Líneas de ensamblaje de jaulas y marcos de refuerzo

- Centros de procesamiento y distribución de varillas de refuerzo

Dondequiera que se necesiten anillos de refuerzo circulares, esta máquina ofrece velocidad, precisión y fiabilidad para cumplir con los estándares industriales.

¿Cómo funciona la máquina de fabricación de anillos de refuerzo con otros equipos?

En plantas de procesamiento de refuerzo, la máquina de fabricación de anillos de refuerzo suele combinarse con unamáquina de enderezado y corte de refuerzoy una dobladora de refuerzo:

Bobina de acero → Enderezado → Formación del anillo → Doblado o ensamblaje

Esta combinación forma una línea de producción automática completa, asegurando un procesamiento suave y eficiente desde la bobina de materia prima hasta la estructura terminada.

Preguntas frecuentes sobre la máquina de fabricación de anillos de varillas de refuerzo

¿Qué tipo de materiales de refuerzo puede manejar?

Funciona con acero de bajo carbono, acero laminado en caliente y acero laminado en frío. También podemos personalizar rodillos para materiales más duros.

¿Es difícil de operar?

No. La operación es sencilla a través de una interfaz de pantalla táctil PLC. Un operador puede gestionar todo el proceso.

¿Qué hay del mantenimiento y las piezas de repuesto?

La estructura es duradera y fácil de mantener. La lubricación regular y el reemplazo oportuno de las piezas de desgaste son suficientes. Shuliy proporciona piezas de repuesto a largo plazo y soporte técnico.

¿Puede producir tanto anillos circulares como en espiral?

Sí. El sistema de formación puede ajustarse para producir anillos de refuerzo redondos, en espiral o en forma de bobina según sea necesario.

¿Cuál es la duración del período de garantía?

Todas las máquinas de fabricación de anillos de refuerzo de Shuliy incluyen una garantía de un año y soporte técnico de por vida.

¿Proporcionan instalación o capacitación en el extranjero?

Sí, podemos ofrecer orientación en línea y soporte de instalación en sitio para proyectos a gran escala o líneas de producción completas.

Conclusión

Nuestra máquina de fabricación de anillos de refuerzo ofrece automatización, precisión y durabilidad en un solo sistema. Es la opción ideal para empresas que buscan una producción eficiente de círculos de refuerzo para proyectos de construcción, puentes y cimientos. Fácil de operar, altamente precisa y construida para durar — convierte el procesamiento de refuerzo en una operación más rápida, inteligente y confiable.

Si está interesado, no dude en contactarnos para más detalles y soluciones personalizadas.