紙製卵トレイ製造機

| 名前 | 卵トレイ製造機 |

| 容量 | 1000-7000 枚/時 |

| 力 | 38-120 KW |

| 電源 | 380 V, 50 HZ |

| サービス | オンサイトでの設置および操作ガイド |

| 保証 | 1年 |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

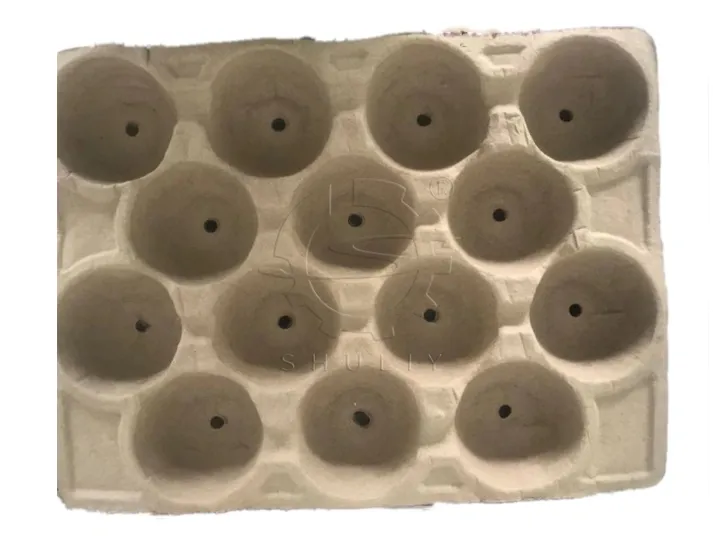

Stable, biodegradable, and cost-effective, paper egg trays have become the preferred choice for producers and consumers worldwide. To meet diverse production needs, we offer egg tray making machines with capacities from 1,000 to 7,000 pcs/h, customizable in color, shape, cavity design, and more—ideal for egg trays, fruit trays, shoe supports, electronic packaging, and so on.

用途:原材料と最終製品

The egg tray making machine uses pulp as its raw material, which is produced by a pulping machine from various types of waste paper—such as old newspapers, cardboard, book paper, corrugated paper, and office waste paper.

Through vacuum forming, the machine shapes the pulp into wet paper trays, which are then transferred to the drying and finishing systems.

The wet trays can be processed into a wide range of eco-friendly packaging products, including:

chicken egg trays, duck egg trays, fruit trays, shoe supports, industrial buffer pads, and electronic product packaging trays.

当社の卵トレイ製造機の主な特徴

- 高度に自動化された材料処理および生産システム 時間と労働コストの節約に役立ちます。

- 生産能力は次の範囲です 1,000から7,000個/時ほとんどの製造ニーズに対応しています。特別な要件に応じたカスタム機械も利用可能です。

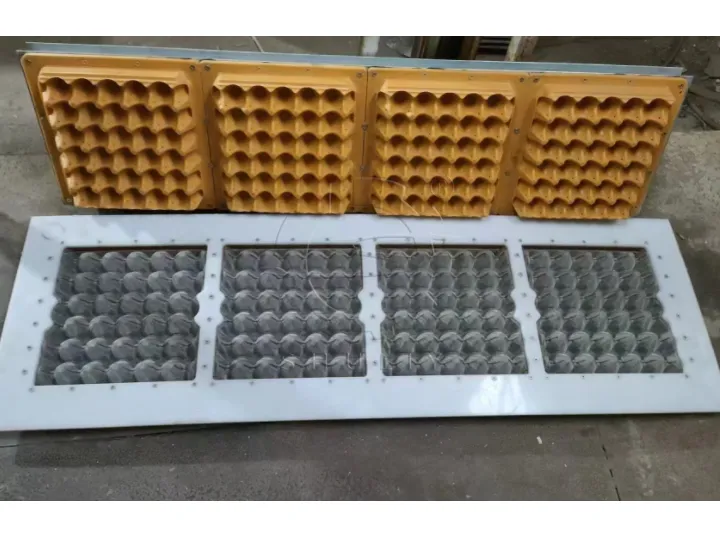

- 金型は完全にカスタマイズ可能です キャビティの数、サイズ、形状、材料の観点から、さまざまなトレイデザインに柔軟に適応できます。

- 金型は次の材料で作られています ステンレス鋼水に対する耐性、腐食に対する耐性、耐久性、メンテナンスや交換の容易さを確保します。

- 完成した卵トレイは特徴です 均一なサイズと厚さクリーンなエッジ、強力な保護構造、完全な生分解性。

- 色の添加剤は、特定の外観やブランドニーズに応じて生産中に適用することもできます。

紙製卵トレイ製造機のマルチモデル

実際の生産要件に応じて、我々はさまざまなモデルの卵トレイ製造機を提供しています。これには、片面、四面、八面があります。仕様は以下の通りです:

片面卵トレイ成形機

片面卵トレイ製造機は1つの作業面を持ち、3*1は1列あたり3つの型、4*1は1列あたり4つの型を意味します。

| モデル | WJ-1000-3*1 | WJ-1500-4*1 |

| 容量 | 1000 個/時 | 1500 個/時 |

| 力 | 38 KW | 38 KW |

| 重さ | 2500 kg | 3000 kg |

| 紙の消費 | 80 kg/h | 120 kg/h |

| 水の消費 | 120 kg/h | 240 kg/h |

| 機械サイズ | 2600*2200*1900 mm | 2800*2200*1900 mm |

四面卵トレイ製造機

四面卵カートン製造機は4つの作業面を持ち、3*4は1面あたり3つの型、4*4は1面あたり4つの型を意味します。

| モデル | WJ-2500-3*4 | WJ-3000-4*4 |

| 容量 | 2500 個/時 | 3000 個/時 |

| 力 | 55 KW | 60 KW |

| 重さ | 4000 kg | 4800 kg |

| 紙の消費 | 200 kg/h | 240 kg/h |

| 水の消費 | 400 kg/h | 480 kg/h |

| 機械サイズ | 2900*1800*1800 | 3250*1800*1800 |

八面卵トレイ製造機

八面の卵トレイ製造機は8つの作業面を持ち、4*8は1列あたり4つの型、5*8は1列あたり5つの型、6*8は1列あたり6つの型を意味します。

| モデル | WJ-4000-4*8 | WJ-5000-5*8 | WJ-7000-6*8 |

| 容量 | 4000 個/時 | 5000 個/時 | 7000 個/時 |

| 力 | 95 KW | 95 KW | 120 KW |

| 重さ | 7000 kg | 8000 kg | 10000 kg |

| 紙の消費 | 320 kg/h | 400 kg/h | 480 kg/h |

| 水の消費 | 640 kg/h | 800 kg/h | 960 kg/h |

| 機械サイズ | 3250*2300*2500 | 3700*2300*2500 | 3200*2300*2500 |

卵ボックス製造機の選び方は?

卵トレイ機の選択は、生産要件、予算、利用可能なスペースなど、いくつかの要因に依存します。

- 片面卵トレイ製造機は、1時間あたり1,000〜1,500個の生産能力を持ち、限られた予算と低い生産能力を持つ小規模ユーザーに適しています。小型で、操作が簡単で、乾燥ラインなしで湿った卵トレイを乾燥させることができます。

- 四面の卵トレイ成形機は、1時間あたり2,000〜3,000個の能力を持ち、中規模の卵トレイ製造業者や、すでに基盤の一部を持つ廃紙リサイクラーに適しています。

- 八面卵トレイ成形機は高速で非常に効率的であり、大規模生産に適しています。

まだどのように選ぶか不明な場合や他の要件がある場合は、カスタマイズされたペーパー トレイ マシンについてお気軽にお問い合わせください。カスタマイズできます:

- 型の数、サイズ、形状

- 材料

- 乾燥方法

当社の卵トレイ生産機の作動原理

The complete paper egg tray making process is as follows:

廃紙 → 製紙 → 型吸着成形 → 湿った卵トレイ → 乾燥 → 完成した卵トレイ

卵トレイ成形機は、真空ポンプを使用して負圧を生成します。これにより、型の表面からパルプが引き寄せられ、卵トレイの形状が作られます。その後、湿った卵トレイはエアコンプレッサーからの正圧によって転送型に吹き付けられ、最終的にメッシュベルトまたはトレイに移されます。その後、乾燥が行われます。

当社の機械で高品質な卵トレイを作りましょう!

効率と品質を向上させた卵トレイの生産をお考えですか?当社の先進的な紙パルプ卵トレイ製造機は、一貫した出力、カスタマイズ可能なデザイン、そして環境に優しい性能を提供します。

今日、無料見積もりとニーズに合わせた専門的なソリューションについてお問い合わせください!