EPS Recycling Machine | Expanded Polystyrene Recycling

| Capacity (kg/h) | 100-500 |

| Raw Materials | EPS, EPS Foam |

| Core Equipment | Crusher, Granulator |

| Machine Color | White, Red (Support Customization) |

| Brand Name | Shuliy |

| Warranty | 12 Months |

| After Warranty Service | Video Technical Support, Online Support, Field Maintenance and Repair Service |

You can now ask our project managers for technical details

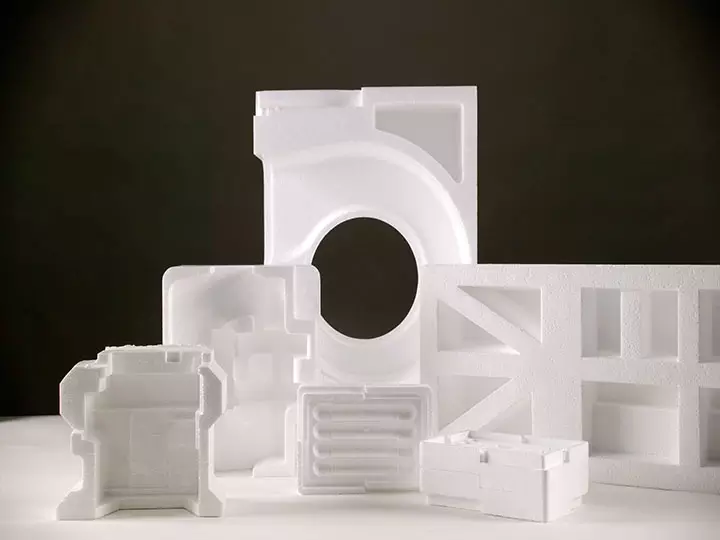

EPS recycling machine can make waste eps foam into plastic pellets for easy transportation and storage. In the whole eps recycling pelletizing line, the main machines include a foam crusher machine, foam granulator, pellet cutter, etc. Next, we will introduce you to the eps foam recycling process in detail. This can give you a new understanding of the plastic recycling industry.

Detailed eps foam recycling process introduction

Crushing

We all know that the foam itself is very large. So, it will take up a lot of space if left untreated. Therefore, we need to use the machine to crush the eps foam into small pieces first. The EPS recycling machine needed at this time is a special EPS foam shredder.

Conveying

Because of the light weight of EPS foam pieces, it is easy to be blown everywhere by the wind. To better solve the conveying problem, the EPS foam conveyor can easily deliver the foam to the pelletizing host.

Pelletizing

The pelletizing process is the most important step in the whole EPS recycling process. The EPS pelletizer is also the most important EPS foam recycling machine. In this step, the pelletizing machine melts the foam material by heating. Then the melted EPS foam will be extruded and drawn through the die in the auxiliary machine. Then we will get the filamentous EPS products.

Cooling

By the above work of foam recycling machine, we can get the filamentary EPS product. But after melting and granulation, the temperature of the filamentary EPS is very high. Therefore, we need to cool it with cold water.

Cutting pellets

The final step is to cut the filamentary EPS thread into pellets.

What EPS recycling machines do we need?

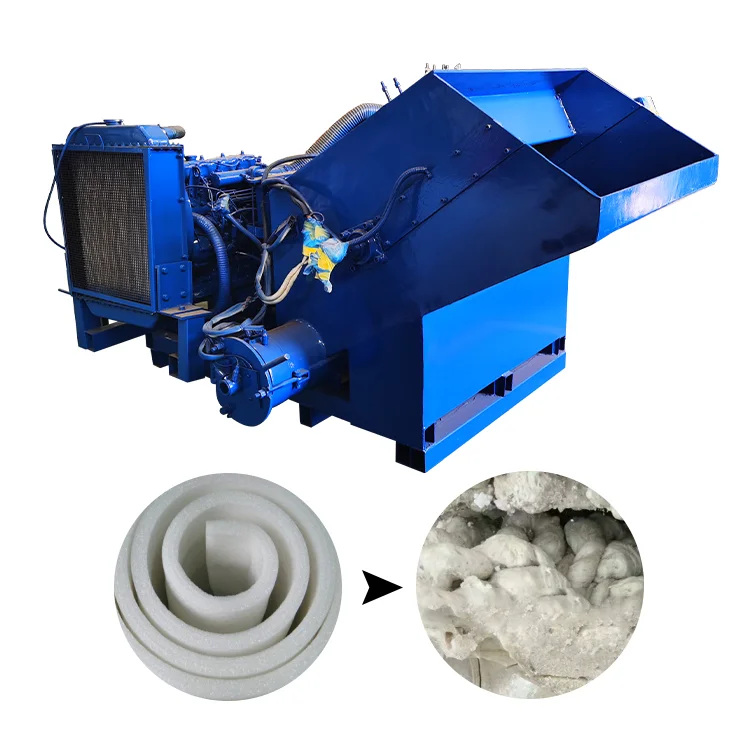

EPS crusher

Purpose: Crushing block EPS foam products into pieces.

EPS foam conveyor

Purpose: It can send the crushed EPS pieces to the granulation main machine

EPS foam pelletizing machine

Purpose: melting and heating EPS foam material

EPS foam pelletizing auxiliary machine

Purpose: To extrude the melted plastic into shredded material in the auxiliary machine through the die head.

Cooling water tank

Purpose: Cooling filament EPS foam

Plastic granules cutting machine

Purpose: to cut the cooled plastic filament into granules

Why more and more people are engaged in the EPS foam recycling industry?

As we all know, EPS packing is a disposable consumable. It is not easy to degrade on its own after disposal. In the past, foam products have caused a lot of pollution to the environment. With the popularity of carbon emission reduction in various countries, EPS waste management has become an important way to protect the environment. EPS foam recycling can not only avoid environmental pollution, but also enable the material to be used repeatedly. Therefore, EPS foam recycling machine is also becoming more and more popular.

The application of recycled EPS pellets

From the above, we know that EPS recycling machine can make plastic pellets from used EPS foam. The important point is that we can’t use waste plastic products to make anything that will come in contact with food. They include insulated cups, foam trays, etc. But we can use it to make outdoor furniture, roof tiles, coat hangers, nursery boxes, window and door frames, packing materials, etc. We can also mix EPS with concrete to make precast concrete blocks.

In addition, when EPS is combined with soil and compost, it helps promote aeration. And when it is mixed with plastics, it can be used to make decorative panels and interior trim.

All in all, if you need foam recycling equipment for your business, please feel free to contact us.