Plastic Granulating Line for PP LDPE HDPE Recycling

| Capacity | 100-500kg |

| Raw Materials | Waste Plastic Bags and Films |

| Core Equipment | Crusher, Plastic Granulator |

| Qty of Automatic Feeder | 1 |

| Qty of Conveyor | 3-4 |

| Type of Plastic Dryer | Vertical |

| Warranty | 12 Months |

| After Warranty Service | Video Technical Support, Online Support, Field Maintenance and Repair Service |

You can now ask our project managers for technical details

The plastic granulating line is the most common production line in plastic recycling lines. So, this line has the purpose of recycling plastic into pellets. The output range of the complete plastic pelletizing line is from 100-500 kg/h.

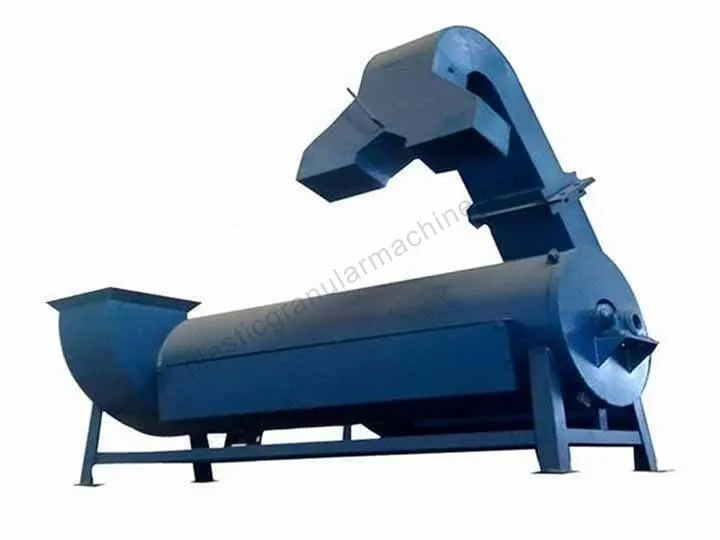

The recycling line includes a crushing and washing machine, plastic film rinsing tank, plastic dewatering machine, plastic pelletizing machine, cooling tank, pelletizing machine, and storage bin.

What is the scope of application of the plastic granulating line?

However, not all plastics can be handled by our plastic recycling granulating line. Our line can only process PP, PE, BOPP, LDPE, and HDPE plastic films. Other plastic materials, such as PET bottles and EPS foam, need to be processed by the PET bottle recycling line and the EPS foam recycling pelletizing line. This also means that special materials require special plastic machines and lines. If you come across a manufacturer that says their one plastic recycling line can handle all plastic materials. Then you need to pay more attention.

How plastic granules are made?

The following is an introduction to the plastic pelletizing process for the plastic granulating line.

Shredding and Cleaning

First, the plastic film needs to be crushed into pieces. While crushing, our plastic processing machine will clean the plastic fragments.

Dewatering

After cleaning, plastic debris will contain a lot of water. Therefore, for better pelletizing results, they need to be dewatered and dried.

Pelletizing

Next is the most important part of the plastic granulating line. The plastic pelletizing machine melts the plastic film and extrudes long strips of plastic.

Cooling

Then the filamentary plastic is cooled to harden it for subsequent cutting.

Pelletizing

After cooling, the long strips of plastic are cut into pellets by cutter.

Storing

Finally, the plastic pellets are stored in storage bins.

The main machine of the plastic granulation line

Plastic crushing machine

The plastic crusher is the first main machine in the plastic recycling granulating line. It can crush plastic film into plastic fragments. In addition, the biggest feature of our plastic crusher is that it can clean plastic fragments after plastic crushing. So this is a crushing and cleaning machine. The built-in special knife is very sharp and can cut the plastic film into small pieces in a short time. The machine adopts a closed sealing design, so it has high safety.

Plastic dehydrator

Efficient plastic dewatering machine is a machine that uses strong centrifugal force to dry the water in plastic fragments.

Plastic granulator machine

Our plastic recycling granulator is a machine that can melt plastic films and extrude long strips of plastic. The whole plastic granulation system includes main machine and auxiliary machine. After melting, the plastic will flow out of the outlet of the main machine and then enter the auxiliary machine. Under the action of the auxiliary machine, the strip-shaped plastic will be extruded from the head grinding tool of the auxiliary machine.

Pellets cutting machine

In order to get plastic particles, you need a plastic granulator to cut long strips of plastic into plastic particles. A pellet cutting machine can help you achieve this. In addition, the size of plastic particles can be adjusted according to your needs.

Plastic granulator for sale

To sum up, we know that the plastic granulator is the key equipment in the whole plastic granulating line. Waste plastic granulation extruder adopts automatic temperature control and electromagnetic heating technology. Therefore, it has the characteristics of less power consumption, no pollution and high degree of automation. In Efficient plastic recycling machinery, we have mini plastic granulator machine and large scale plastic granulators for sale. The following are the parameters of three plastic granulators. If you want other machines, please feel free to contact us.

| Model | SL-125 | SL-150 | SL-180 |

| Screw diameter | 125mm | 150mm | 180mm |

| Main shaft speed | 50-70min | 40-60min | 40-50min |

| Main motor | 22+1.5lw | 30+1.5kw | 45kw |

| Capacity | 3t/day | 5t/day | 7t/day/ 24h |

Characteristics of plastic granulating line

- High output. The output of the production line is high, and the maximum output per hour can reach 1000 kg.

- Widely used. Our recycling line can Granulation plastic films of various raw materials. What’s more, the most common raw materials include PP, PE, BOPP, LDPE, and HDPE.

- Easy to operate. Because the whole plastic pelletizing line only needs 3-4 people.

- Degree of automation.

- Long service life. The whole production line is made of durable steel. Therefore, it has the characteristics of ruggedness and durability.

3D video of plastic film granulating process

F&Q

- My raw materials are PP, PE, PET, PVC, PS, and other plastic products. Can I use the same production line for granulation?

A: No, different raw materials have different treatment processes. (because different raw materials have different melting points) - If the raw materials are PP and PE, what is the temperature required for granulation? What is the maximum temperature of the machine?

A: 240 degrees Celsius is enough. What’s more, the maximum working temperature of the machine can reach 500 degrees. - What is the power consumption of the whole plastic pelletizing line?

A: the power consumption of a ton of material is about 500 degrees. - What is the material of the screw and die of the granulator?

A: 38 Luo manganese steel /40 Luo - How do distinguish the model of the extrusion pelletizing machine?

A: The model is divided according to the inner diameter of the screw. - How to make particles of different colors? Is there a formula?

A: add pigment when granulating. The formula can be provided only after placing an order. - How many people do I need to operate the whole plastic granulating line?

A: 3-4 people are enough

All in all, if you need plastic granulating services, please feel free to contact us.