Plastic Strip Cutting Machine

| Machine brand | Shuliy Group |

| Model | SL-180, SL-220, SL-260 |

| Width of knives | 180mm. 220mm, 260mm |

| Type of knive | Hob |

| Warranty | 12 months |

You can now ask our project managers for technical details

Plastic pelletizer is the last step of the pelletizing line, it will cut the long plastic strips into small pellets for subsequent packaging and sales.

Application of plastic strip cutting machine

It is suitable for plastic pelletizing machines after pulling strips, used for PVC, PP, LDPE, HDPE, LLDPE and other plastic pelletizing.

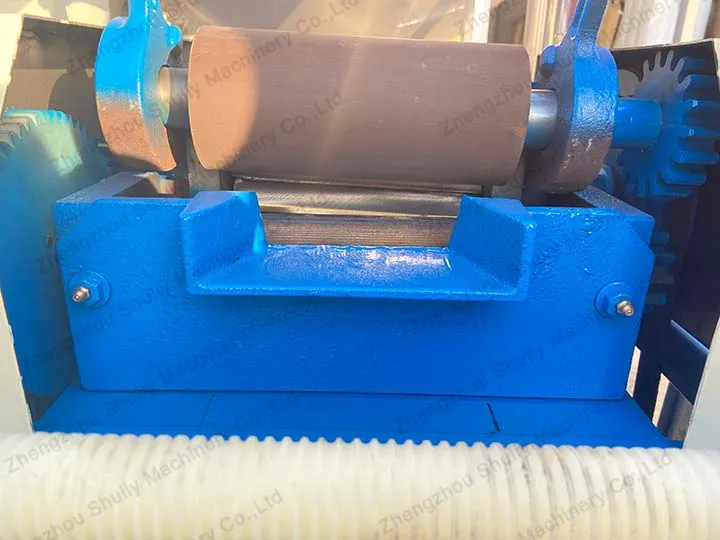

Plastic pellet cutting machine structure

Plastic pelletizer is mainly composed of hob, pressure roller and transmission device.

Plastic strip cutting machine parameters

| Type | Power | Width of knives | Knive type |

| SL-180 | 3 | 180 | hob |

| SL-220 | 5.5 | 220 | hob |

| SL-260 | 5.5 | 260 | hob |

Plastic pellet cutting machine operation shall be noted

- Operator filler, must look good, do not enter the material debris, grasp the temperature.

- Water temperature should generally be in 50 – 60 ℃, low easy to break the strip, beyond easy to stick. At the beginning of the water temperature is not stable, cut grain can be used to cut grain machine conveyor for a period of time, and so the water temperature rises and then let the plastic pellet cutting machine automatically cut the plastic, so as not to break the strip.

- Cutting granules must be pulled evenly before the strip into the pressure roller, otherwise it will damage the plastic pellet cutter.

Related plastic pelletizing line

The whole plastic pelletizing line include plastic granulators, plastic crushers, plastic washing machines and plastic strip cutting machines. If you are a plastic recycling factory or going to start a new recycling business, feel free to contact us any time. We will customize a complete plastic pelletizing solution for you.