Die Head for Plastic Pelletizer

| Brand | Efficient Machinery |

| Application | Key parts of the plastic extruder |

| Types | Electric gear die head, hydraulic die head, etc. |

| Materials | High-quality stainless steel |

| Warranty | One year |

| Services | Technical support and on-site installation. |

You can now ask our project managers for technical details

There are three types of die heads for plastic pelletizer machines, the hydraulic die head, the electric gear die head, and the automatic die head. They are important components of the plastic pellet machine.

Die Head for Plastic Pelletizer Introduction

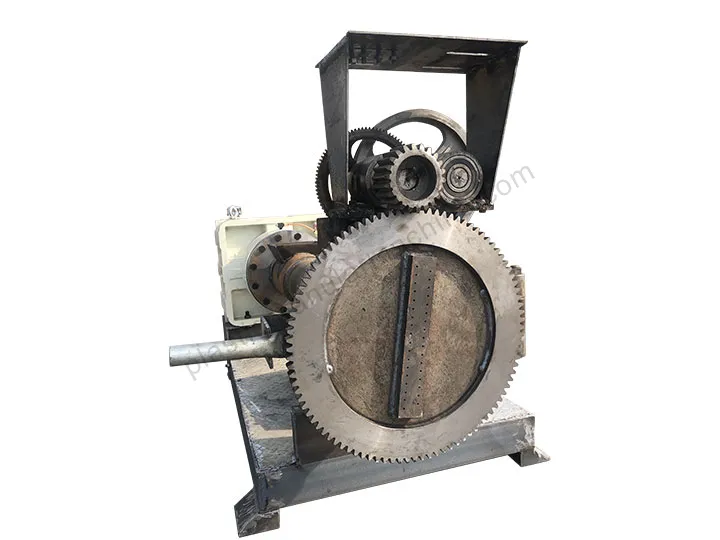

Electric Die Head

Working principle: Electric gear die head adopts electric gear mechanism for control, through the motor driven gear movement, to realize the extrusion and molding of pellets. The principle of operation is relatively simple and is suitable for some small to medium sized pellet machines.

Advantages: Electro-gear die heads are generally low-cost and relatively easy to maintain compared to hydraulic die heads. This makes them a cost-effective choice for some small to medium-sized lines.

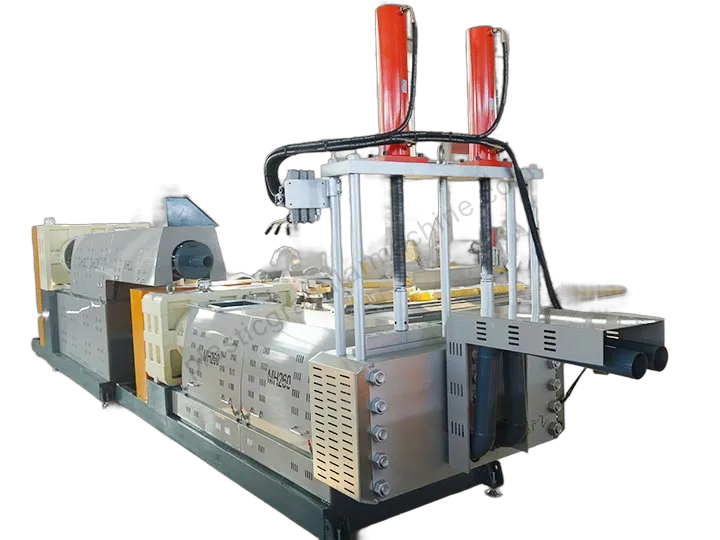

Hydraulic Die Head

Working Principle: The hydraulic die head is controlled by a hydraulic system which provides precise control of the die head for high quality pellet production.

Adantages: The hydraulic die head offers a high degree of adjustment flexibility, allowing the diameter and length of the pellets to be adjusted in real time according to production needs. This flexibility is important to meet the needs of different customers and markets.

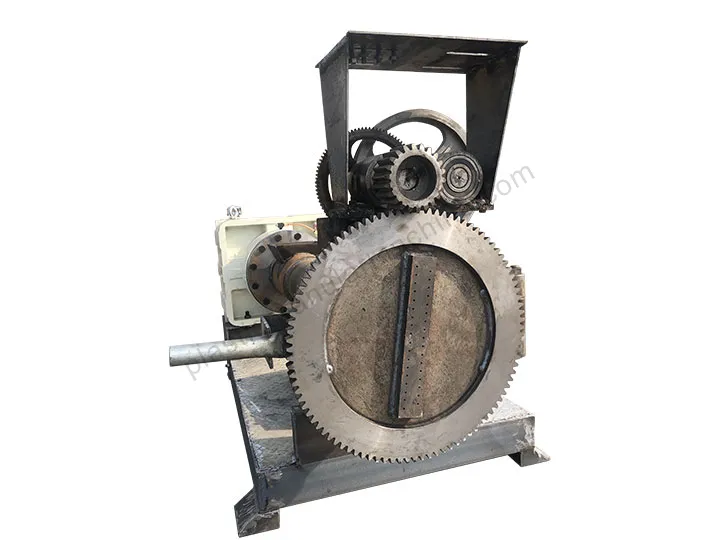

Automatic Slag Filter

Working Principle: The molten plastic enters the die assembly, when passing through the screen of the plastic extrusion tooling, the large pore size impurities are intercepted and the molten plastic passes through smoothly.

Advantages: Effective removal of contaminants from the melt reduces maintenance costs for subsequent machine processing. Automatic filter molds are suitable for handling dirty plastics.

Plastic Granulator Die Head Video

Common Configurations of Plastic Extrusion Die Head

The die head for plastic pelletizers is an important part of the plastic extrusion molding process, affecting the shape, size, and quality of the finished pellets. Plastic extruders are used in conjunction with cooling tanks, pellet cutters, etc. to produce high-quality plastic granules.

The modular design of the plastic granulator allows you to match freely according to your production needs. If you are interested in granulation or don’t know how to choose, please contact us, and we will give you advice!