Tire Shredder Machine for Sale

| Name | Tire shredder machine |

| Raw Materials | Whole tire, tire blocks, or rubber blocks |

| Final Products | 50-100 mm adjustable tire blocks |

| Capacity | 2-20 t/h |

| Services | On-site installation and operation guides |

| Warranty | One year free |

You can now ask our project managers for technical details

The tire shredder machine for sale plays a key role in the tire recycling process and rubber powder production by efficiently shredding large scrap tires into small pieces, approximately 50-100 mm, that can easily be sold or transported. These pieces can also be ground into fine rubber powder.

How to Apply the Waste Tire Shredder?

Our tire shredders can handle many types and sizes of scrap tires, including car, truck, agricultural, and OTR (off-the-road) tires. They can process standard tires with diameters of less than 1,200 mm and oversized mining tires, such as R35, R49, R51, and R63.

Depending on the model’s configuration, the tire shredder machine for sale can directly feed and process the following raw materials:

- Complete tires (diameter ≤1400 mm)

- Cut or disintegrated engineering tire blocks

- Pre-treated rubber blocks

- Components such as sidewalls and crowns

The shredded product output is adjustable-size rubber blocks (typically 50-100 mm), which are well-adapted to the next processing step. These blocks are easy to store and transport and can be fed directly into the rubber grinding system for producing fine rubber granules or powder.

Main Features of Our Tire Shredding Machines

Our tire shredder machine for sale has a competitive advantage in the market due to its professional configuration and performance characteristics.

- High-precision knife shaft system: Neat cutting surface; improves the quality of finished rubber block products.

- High-torque dual-axis structure: Strong cutting force; easily handles whole tires and tire blocks.

- Wide applicability: It is suitable for a wide range of tire types and sizes, including OTR engineering tires.

- Flexible capacity: 2-20 tons per hour to meet the needs of different production lines.

- Adjustable discharge control: The discharge size can be precisely set within 50-100 mm to produce uniform particles.

- Wear-resistant blade material: It is made of high-strength, corrosion-resistant stainless steel for a long life.

- Strong compatibility: Can be integrated into various types of tire recycling systems to achieve efficient linkage.

- Perfect after-sales service: Including warranty support, door-to-door installation, technical guidance, and so on.

This industrial rubber shredder series has both performance stability and industrial adaptability and is the ideal choice for all scales of tire shredding business.

Specifications List of the Tire Shredder Machine for Sale

We provide various rubber tire shredders. Some main parameters are as follows:

| Model | Applicable Raw Material | Max Tire Feed Size | Output Size (Rubber Chips) | Processing Capacity | Total Power | Application Type | Blade Specs | Machine Weight | Footprint (L×W×H) |

|---|---|---|---|---|---|---|---|---|---|

| SL-900 | Car tires, small truck tires | ≤900 mm | 50 mm | 2 t/h | 64.5 kW | Compact car tire shredder | Dia. 360mm / 16 blades / 50mm thick | 10 tons | 9*5*2.8 m |

| SL-1000 | Car & light truck tires | ≤1000 mm | 60 mm | 4 t/h | 94.5 kW | Entry-level tire crushing machine | Dia. 440mm / 16 blades / 50mm thick | 13 tons | 10*6*3.2 m |

| SL-1200 | Passenger & disassembled OTR tires | ≤1200 mm | 60 mm | 5–6 t/h | 157 kW | Mid-scale rubber tire chipper | Dia. 510mm / 18 blades / 60mm thick | 15.8 tons | 10*6*3.2 m |

| SL-1500 | Whole truck tires, large OTR tire blocks | ≤1200 mm | 75 mm | 8–10 t/h | 188.5 kW | Heavy-duty industrial tyre shredder | Dia. 580mm / 20 blades / 75mm thick | 18.6 tons | 20*10*3.5 m |

| SL-1800 | Full-size OTR tires (e.g. R51–R63) | ≤1400 mm | 100 mm | 15–20 t/h | 328.5 kW | High-output tire shredder machine for sale | Dia. 650mm / 18 blades / 100mm thick | 26 tons | 20*12*4 m |

If you have other production needs, please feel free to leave messages, and we can provide a customized tire shredder machine for sale.

How Does the Tyre Crusher Machine Work?

Working steps of the tire shredder machine for sale:

- Feeding: Whole tires or blocks of waste tires are evenly fed into the shredding chamber via a conveyor belt.

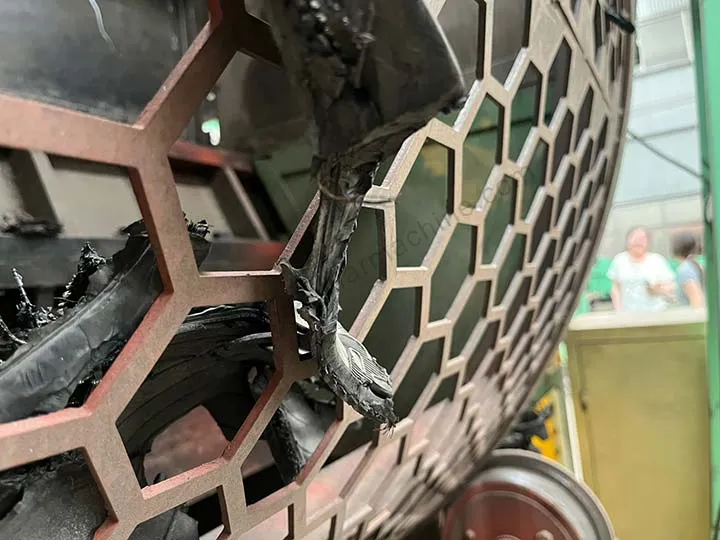

- Dual Shaft Shearing: Two low-speed, high-torque knife shafts rotate in reverse synchronously and use high-strength alloy blades to shear, tear, and crush the tires.

- Size Control: Through blade spacing and screen mesh design, the size of the discharged material can be controlled within the 50-100 mm range to meet different reuse requirements.

- Initial separation of steel wires: The shredding process loosens most of the steel wires inside the tires for subsequent magnetic separation.

- Discharge conveyance: Shredded rubber blocks are conveyed via a discharge belt to the next process, such as grinding, granulating, or baling.

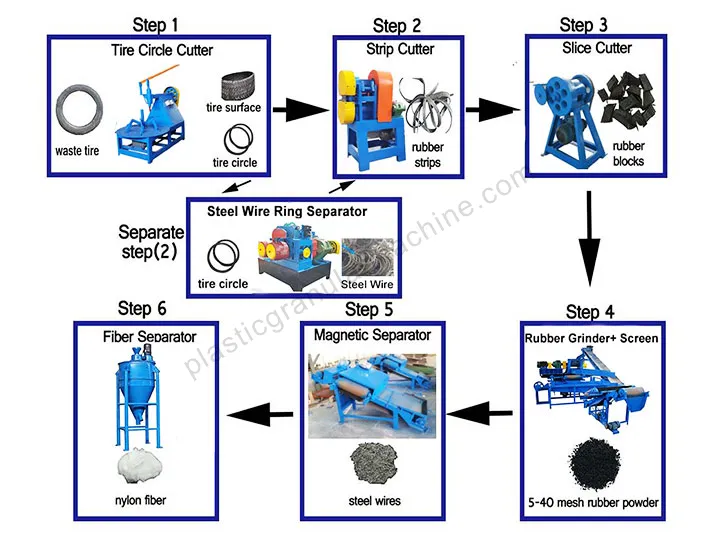

How Rubber Tire Shredder Machines Fit into a Full Recycling System?

In the complete tire recycling process, waste tires first undergo pre-processing, which includes steel wire removal and chopping. Then, they are sent to the rubber tire shredder for initial crushing, which generates uniformly sized rubber blocks that are easy to process further.

Next, the rubber blocks enter the tire granulator for deep grinding to produce fine rubber powder. This powder can be used in the production of recycled rubber products, such as rubber floor tiles, runway materials, and seals.

Application of the Output from Tire Shredder Machine for Sale

Though not yet in a powdered state, rubber blocks produced with waste tire shredders have a wide range of industrial and commercial value.

- Fuel substitute: They can be used as industrial fuel to replace coal and oil. It is commonly used in the high-temperature incineration processes of cement plants, power plants, and paper mills.

- Foundation and Landfill Engineering: It can be used for road and railroad bedding with good drainage and cushioning.

- Shock-absorbing mats and cushioning materials: Rubber blocks can be used as filling material for sports grounds, playgrounds, and anti-vibration mats in construction.

- Processed into rubber powder: Further grinding can produce more detailed rubber granules or powder, which can be used for rubber floor tiles, artificial turf matting, sealing rings, and more.

- It can be used as a raw material for rubber molding products, such as rubber car stoppers, speed bumps, floor tiles, gaskets, and other recycled products.oducts, the tire shredder is an indispensable piece of equipment in modern waste tire recycling systems.

Where Can We Export Our Rubber Tire Shredder To?

Our commercial tire shredder for sale can be customized for clients around the world. Nowhere you are, we can provide transportation, technical guidance, and on-site installation service.

With superior performance and favorable tire shredder machine price, our tyre shredder for sale South Africa, tyre shredder for sale in Australia, tire shredder for sale UK, and so on. gained a wide range of unanimous praise! If you’re interested, please feel free to contact us!