Rebar Bending Machine

| Name | Rebar bending machine |

| Raw Materials | waste rebars |

| Final Products | Rebar bent at a specified angle |

| Capacity | Customized solutions |

| Warranty | One year free |

| Services | Technical support and on-site installation. |

You can now ask our project managers for technical details

Looking for a reliable rebar bending machine that handles daily construction workloads? EFFICIENT builds disk‑type rebar benders for round and deformed bars with stable torque, precise angle control, and long service life. Choose from compact manual models to automatic CNC rebar bending machines to match your bar size, speed, and budget.

Why Choose Our Rebar Bending Machine?

- Wide capacity, one lineup: bend round bar up to 60 mm and deformed (threaded) rebar up to 50 mm, model‑dependent.

- Fast cycle time: up to 12 bends per minute. Keep projects on schedule, whether on site or in a fab shop.

- Accurate and repeatable: hardened disk and pins with precise angle stops; CNC options store programs and compensate spring‑back.

- Built for tough jobs: thick‑plate welded frame, industrial reducer, copper‑wound motors (3.0–5.5 kW), 1440 r/min, 3‑phase 380 V.

- Easy to operate: clear angle setting, foot pedal, quick pin changes, safe guards, E‑stop.

- Low maintenance: accessible grease points, replaceable pins, labeled electrics. Downtime is minimal.

- Full solution ready: pair with our Rebar Straightening Machine and Rebar Ring Making Machine to streamline your line from prep to forming.

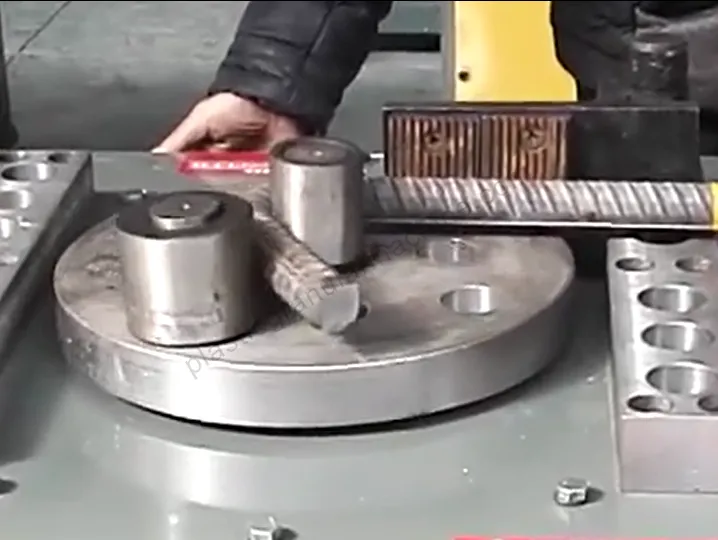

How Does the Rebar Bender Machine Work?

- A rebar bending machine drives a heavy turntable through a motor and worm‑gear reducer to deliver low‑speed, high‑torque rotation.

- The rebar is located against side stops while a center mandrel pin sets the inner bend radius; a bending pin on the turntable sweeps the bar around the mandrel to create a plastic bend.

- Rotation stops at preset angles via mechanical stops or limit switches and can reverse to release the workpiece.

- Bend radius is adjusted by changing the mandrel diameter and the hole position of the bending pin, while jog/forward‑reverse control ensures accurate angles with minimal springback.

Technical Data of the Steel Bar Bending Machines

| Model | Round bar capacity (mm) | Deformed/Threaded capacity (mm) | Speed (bends/min) | Motor power (kW) | Voltage | Motor speed (r/min) | Dimensions (mm) | Weight (kg) | Control |

|---|---|---|---|---|---|---|---|---|---|

| 40 | ≤ 32 | ≤ 28 | 12 | 3.0 | 3-phase 380 V | 1440 | 810*760*830 | 220 | Manual |

| 40H | ≤ 34 | ≤ 32 | 12 | 3.0 | 3‑phase 380 V | 1440 | 830*770*830 | 255 | Manual |

| 42 | ≤ 34 | ≤ 32 | 12 | 3.0 | 3‑phase 380 V | 1440 | 830*750*840 | 270 | Manual |

| 45 | < 40 | ≤ 34 | 12 | 4.0 | 3‑phase 380 V | 1440 | 850*750*830 | 290 | Manual |

| 45 (CNC) | < 40 | ≤ 34 | 12 | 4.0 | 3‑phase 380 V | 1440 | 850*750*830 | 300 | CNC |

| 50 | ≤ 50 | ≤ 45 | 12 | 4.0 | 3‑phase 380 V | 1440 | 950*850*850 | 320 | Manual |

| 50 (CNC) | ≤ 30 | ≤ 28 | 12 | 4.0 | 3‑phase 380 V | 1440 | 950*850*850 | 325 | CNC |

| 60 | < 60 | < 50 | 12 | 5.5 | 3‑phase 380 V | 1440 | 1050*870*900 | 420 | Manual |

| 60 (CNC) | < 60 | < 50 | 12 | 5.5 | 3‑phase 380 V | 1440 | 1050*870*900 | 425 | CNC |

Note: Specs below reflect standard configurations. Custom voltage, pins, and capacity are available.

How to Apply Rebar Bending Machines?

- Structural fabrication: L‑bars, U‑bars, hooks, stirrup shapes, multi‑angle parts for beams, columns, slabs, foundations.

- Job sites and workshops: consistent daily bending with simple setup and quick changeovers.

- Precast and processing lines: integrate with straightening and cutting for smooth flow.

How to Select Your Model?

- Max diameter first: choose by your largest round and deformed bar. Don’t underspec capacity.

- Productivity target: repetitive angles → CNC; mixed small batches → manual/automatic.

- Power and space: confirm 3‑phase 380 V supply, footprint, and weight logistics.

- Tooling set: prepare pin kits and spacers to achieve required bending radii per code.

Tell us your max diameter, typical shapes, and daily output target. We’ll recommend the right rebar bending machine and send a fast quote with lead time and shipping options.

Conclusion

As experts in rebar recycling, we offer comprehensive solutions including rebar straightening machines, rebar ring making machines, rebar bending machines, and more. If you’re interested, please feel free to contact us anytime.