Paper Pulping Machine for Egg Tray Making

| Name | Paper pulping machine |

| Raw Materials | Waste papers |

| End Products | Paper pulp for paper tray making |

| Power | 7.5-45 KW |

| Services | On-site installation and operation guides |

| Warranty | One year free |

You can now ask our project managers for technical details

At the heart of every successful egg tray or pulp molding production lies a powerful pulping system. Our industrial-grade paper pulping machine is engineered for robust, continuous operation, delivering the consistent, high-quality pulp slurry your business depends on. This machine is the foundational first step, transforming low-cost waste paper into the valuable raw material for your entire production line.

What is a Hydro Pulper?

A hydro pulper, also known as a paper pulping machine, is a mechanical vat designed to efficiently break down raw materials like waste paper, old cartons, and cardboard into a fibrous slurry. It is the essential core of any modern pulping system, directly impacting the final product’s quality, strength, and appearance. Without a reliable paper pulping machine, achieving high production efficiency and consistent output is impossible.

Engineering Advantages of Our Paper Pulping Machine

Our design focuses on durability, efficiency, and operational simplicity to maximize your return on investment.

Efficient Pulping with Vortex Action

The machine’s high-speed impeller generates a powerful vortex, creating strong centrifugal force. This force causes the waste paper and water to violently circulate and collide with the machine’s inner components and each other. This process ensures rapid disintegration. A typical batch of waste paper can be processed into uniform pulp in just 20-40 minutes, depending on the material’s toughness.

Robust Construction for Longevity

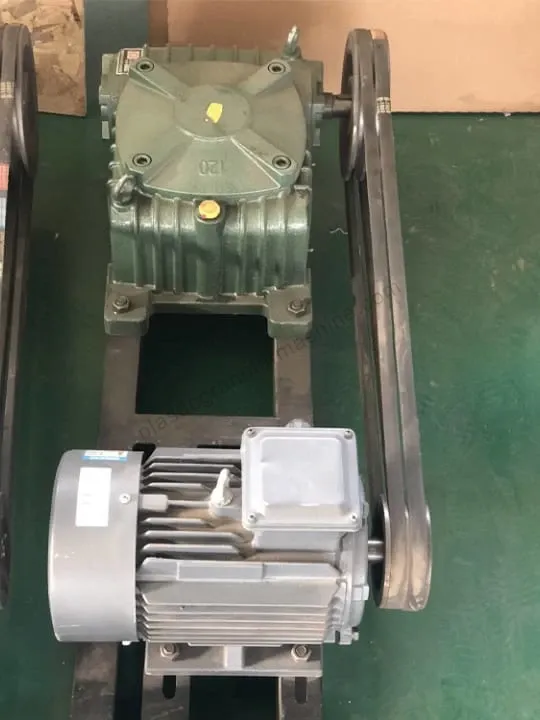

Built from heavy-duty steel, our hydro pulper is designed to withstand the demanding environment of continuous industrial use. Key components, including the motor and drive system, are selected for their reliability and long service life, ensuring minimal downtime for your operation.

Versatile Raw Material Processing

This equipment is not limited to a single type of paper. Whether you are using old newspapers, office waste, or need a dedicated cardboard pulping machine for tougher corrugated materials, our design effectively handles a wide range of inputs, giving you flexibility in sourcing your raw materials.

How Our Cardboard Pulping Machine Works?

The process is straightforward and effective:

- Feeding: Waste paper is loaded into the pulper vat along with a measured amount of water.

- Pulping: The motor drives the impeller, creating the high-velocity vortex that breaks the paper down into individual fibers.

- Discharging: Once the desired consistency is achieved, the finished pulp slurry is discharged, ready to be transferred to the egg tray molding stage of your production line.

Technical Specifications of the Paper Pulper

Choose the right model to perfectly match your production capacity. The following specifications detail our core range of paper pulping machines.

| Model | Volume | Power (kW) | Recommended Molder Size (Arms * Sides) |

|---|---|---|---|

| SL-1.2 paper pulping machine | 1.2 m³ | 7.5 kW | WJ-1000-3*1, WJ-1500-4*1 |

| SL-2.5 cardboard pulping machine | 2.5 m³ | 11 kW | WJ-1000-3*1, WJ-3000-4*4 |

| SL-4 paper pulp making machine | 4 m³ | 18.5 kW | WJ-4000-4*8 |

| SL-5 paper pulper | 5 m³ | 22 kW | WJ-5000-5*8 |

| SL-6 pulper machine for paper | 6 m³ | 30 kW | WJ-7000-6*8 |

| SL-7 hydro pulper | 7m³ | 45 kW | WJ-7000-6*8 |

Note: Custom models are available to meet specific capacity requirements.

Your Reliable Partner for Pulping Solutions

Investing in the right paper pulping machine is critical for the profitability and stability of your business. We provide not just a machine, but a reliable solution backed by technical expertise. We ensure you receive a durable, high-performance pulper that forms the dependable heart of your egg tray production line for years to come.

Ready to build a reliable and profitable pulp molding line? Contact our engineers today to discuss your project requirements and receive a no-obligation technical proposal and quote.