500kg/h PET Bottle Recycling Line To Bhutan| Turnkey Solution

Recently, Efficient delivered a complete, turnkey PET bottle recycling line to a client in Bhutan. This solution allows our client to easily convert waste plastic into high-quality recycled flakes and pellets, providing environmental and economic benefits. Our comprehensive service takes care of all concerns related to equipment configuration, installation, and operation.

Challenges and Needs Faced by Our Customer

The original goal of this Bhutanese client was to transform the growing volume of discarded PET bottles into a commercial opportunity. He planned to set up an efficient and reliable plastic bottle recycling line to manufacture high-quality recycled bottle flakes and pellets for distribution to the market.

However, as an inexperienced investor, he encountered challenges with equipment selection, process design, and international procurement. Consequently, he began seeking a professional partner capable of providing comprehensive support. His core requirements were clear:

- Processing Capacity: The washing line must have a throughput of 500 kg per hour.

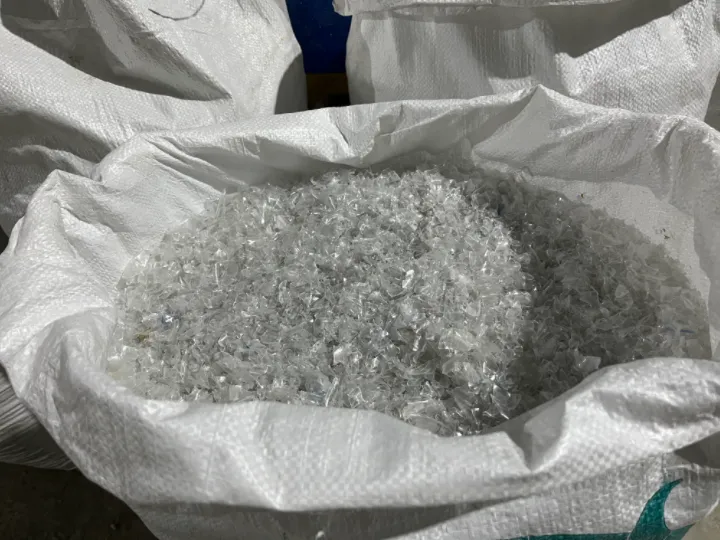

- Final Product: It must be capable of consistently producing high-purity PET flakes and recycled pellets suitable for direct use in downstream industries.

- Turnkey Solution: A single supplier provides all necessary equipment, from shredding and washing to pelletizing, ensuring seamless integration across all stages.

- International Support: The supplier must have extensive experience with multinational projects and be able to provide reliable remote and on-site technical support for the factory in Bhutan.

EFFICIENT Solution: Customized One-Stop PET Bottle Recycling Line

EFFICIENT engineered a comprehensive turnkey solution, meticulously designed to meet the client’s specific requirements for capacity, product quality, and operational simplicity. The solution was divided into two integrated stages: a high-efficiency PET bottle washing line and an advanced pelletizing system.

PET Bottle Recycling Line

| Process Step | Key Equipment | Function & Benefits |

|---|---|---|

| 1. Shredding | Double-Shaft Shredder | It tears apart compressed bottle bales. This ensures a steady, even flow of material into the PET bottle recycling line. |

| 2. Crushing | High-Speed Wet Crusher | This machine crushes bottles into small, uniform flakes. Water is used in the process. This provides a first wash and helps the blades last longer. |

| 3. Washing & Separation | Friction Washer & Sink Float Tank | High-speed friction scrubs the flakes clean. It removes dirt, glue, and old labels. A water tank then separates materials. Heavy PET flakes sink. Lighter plastic caps float and are removed. |

| 4. Drying | Dewatering Machine & Thermal Dryer | First, a high-speed machine spins most of the water off. Then, a thermal dryer uses hot air to finish the job. Final moisture is under 1%. This is critical for top-quality flakes. |

PET Flake Pelletizing Line

| 5. Extrusion | Two-Stage Vented Extruder | Our two-stage extruder melts and filters the plastic flakes. It also removes trapped gases. The result is solid, bubble-free pellets. Perfect for reuse. |

| 6. Cooling & Cutting | Water Trough & Pelletizer | Hot plastic strands exit the extruder. They are instantly cooled in a water bath. A pelletizer then cuts them into small, uniform pellets. |

| 7. Storage | Storage Silo | Finished pellets are moved to a large storage silo. They are kept clean and safe. Ready for bagging and shipping. |

Excellent Results Of Our PET Bottle Recycling Lines

By partnering with Efficient, Bhutanese clients gain a high-performance recycling system and a trusted technical partner.

- Enhanced Reliability: We maintain a stock of spare parts, including cutting tools, and commit to rapid delivery within 30 business days, maximizing operational efficiency for our clients.

- Global Service Capabilities: We provide detailed installation drawings and 24/7 online technical guidance. Additionally, we are prepared to send experienced engineers to Bhutan for on-site installation and commissioning, showcasing EFFICIENT’s ability to support clients around the globe.

- Sustainable Future: Once operational, this production line will help our client establish a benchmark circular economy project in Bhutan and contribute to local environmental conservation efforts.

Why Choose Our Plastic Bottle Recycling LIne?

The Bhutan project is further proof of EFFICIENT’s commitment to providing exceptional plastic recycling solutions to clients worldwide. We are more than just equipment suppliers; we are your long-term partners in achieving your recycling goals.

Would you like to turn plastic waste into wealth? Contact our experts today to receive a customized recycling solution and quote!