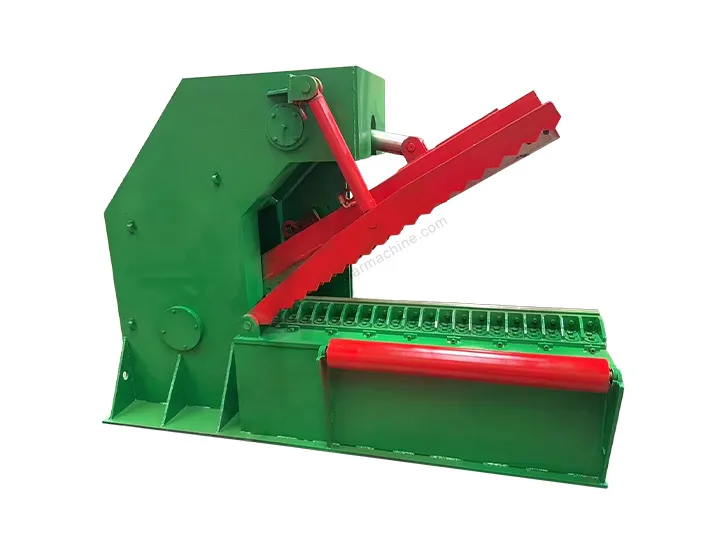

Standard Waste Tire Cutting Machine & OTR Tyre Cutter

| Name | Waste tire cutting machine |

| Model | Standard/ OTR tire cutter |

| Application | 900-1200 mm or 1400-4000 mm tires |

| Output | 60 pcs/ 120 cuts per hour |

| Blade material | Cr12MoV alloy steel |

| Services | Technical support and on-site installation. |

| Warranty | One year fress |

You can now ask our project managers for technical details

In fully automatic rubber powder production lines, the waste tire cutting machine is important equipment used to pretreat tires before shredding. It cuts complete tires into 2-3 sections that are easy to put into the subsequent tire shredder.

We offer two types of efficient tire cutters that can process standard automotive tires up to 1200 mm in diameter and OTR tires from 1400 to 4000 mm, respectively.

Learn More About Our Two Types of Tire Cutter Machines

Our scrap tire cutters adopt alloy blades and hydraulic technology to ensure efficient, fully automatic cutting. Below are the main parameters of these two hydraulic tire cutters. Such as color, blade material, etc., can be customized according to your production needs. Thus, please contact us for more details!

| Model | Standard Tire Cutter Machine | OTR Waste Tire Cutting Machine |

|---|---|---|

| Applicable Tire Size | 900–1200 mm (without bead wires) | 1400–4000 mm (without bead wires) |

| Output Size | Tire blocks under 900 mm | Large slices (approx. 2 cuts/min) |

| Capacity | 60 tires/hour | 120 cuts/hour |

| Power | 7.5 kW | 7.5 kW |

| Machine Size | 1.7*0.8*1.85 m | 3.13*1.65*2.7 m |

| Machine Weight | 1400 kg | 7200 kg |

| Blade Material | Cr12MoV alloy steel | Cr12MoV alloy steel |

| Application | Cutting car, small truck tires before shredding | Cutting giant OTR tires in mining recycling |

Detailed Working Steps of the Waste Tire Cutting Machine

Although our two waste tire cutting machines are designed for different types and sizes of tires, they share the same basic operating principles and procedures.

- Loading: Securely place the tire, with the steel wires removed, on the platform below the blade.

- Startup: Activate the hydraulic system to drive the upper blade downward.

- Cutting: The upper blade forms a cutting surface with the lower fixed blade seat to efficiently cut the tire.

- Reset: Once cutting is complete, the hydraulic system reverses direction and automatically resets the upper blade. Then, the next cutting cycle can be performed. The cut tire can then be fed into a tire shredder for further processing.

Main Features of Our Hydraulic Tire Cutter Machines

- Available for both standard and OTR tire cutting

- Hydraulic-driven system ensures high pressure and continuous cutting efficiency

- Equipped with high-strength serrated blades for strong grip and cutting force

- Cutter body made of wear-resistant alloy steel for durability

- Moderate power, three-phase electric drive for energy efficiency

- Optional fully automatic operation with simple and safe control

- Standard and OTR waste tire cutting machines can be seamlessly integrated into recycling lines, working with tire shredders, grinders, and more

Integration of Tire Cutters in Rubber Powder Recycling Lines

Tire cutting machines are essential in tire recycling, serving as the first step to reduce tire size for further shredding and grinding.

▶ For Standard Tires (≤1200mm)

We offer both semi-automatic and fully automatic waste tire recycling lines.

The standard scrap tire cutting machine is typically used in fully automated systems, working alongside:

- Bead wire remover → Tire cutter → Tire shredder → Rubber grinder

This setup ensures efficient steel removal and tire downsizing for smooth powder processing.

We also offer an integrated bead and cutting machine, which, when paired with a steel separator, provides another complete automatic preprocessing solution.

▶ For OTR Tires (1400–4000mm)

We provide two flexible OTR tire recycling solutions:

- Plan A:

OTR tire debeader→ OTR waste tire cutting machine → Tire shredder → Rubber granulator - Plan B:

OTR tire dismantler machine → OTR tire cutter → Waste tire shredder → Tire grinder

These machines are specially designed for oversized mining tires, including R63, ensuring reliable size reduction and high-efficiency recycling.

How To Choose the Right Rubber Tire Cutter for Preprocessing?

Based on the information above, you now have a basic understanding of the different tire cutting machines. So, how do you choose the right one?

1. Determine Tire Size and Type

- Tire diameter > 1400 mm: Use the OTR tire cutting machine, suitable for large off-the-road (OTR) and mining tires.

- Tire diameter ≤ 1200 mm: Proceed to choose between semi-automatic and fully automatic options.

2. Choose Cutting Method Based on Your Budget and Capacity

- If you have a limited budget or smaller-scale operation, a semi-automatic tire recycling solution — including tire sidewall cutter, strip cutter, and block cutter — is a practical and economical choice.

- If you need high efficiency, automation, and reduced labor, go with our fully automatic standard waste tire cutting machine.

Still unsure? Never mind! Our experienced sales team will help you select or customize the ideal tire cutting solution for your specific recycling needs. Please feel free to contact us!