How to turn plastic into pellets?

Plastic products play an important role in our daily life, but discarded plastic products also bring great pressure on the environment. To solve this problem, the recycling of plastic pellets has become particularly important. Today, we will show you how waste plastic is recycled and converted into plastic pellets. The main process includes crushing waste plastics to pieces and then melting them.

Shredding

Waste plastics are first sent to the plastic shredder for crushing, breaking large plastic materials into small particles for subsequent processing.

Washing

The crushed plastic pellets will be sent to the washing equipment for cleaning to remove the surface dirt and impurities to ensure the purity of the pellets.

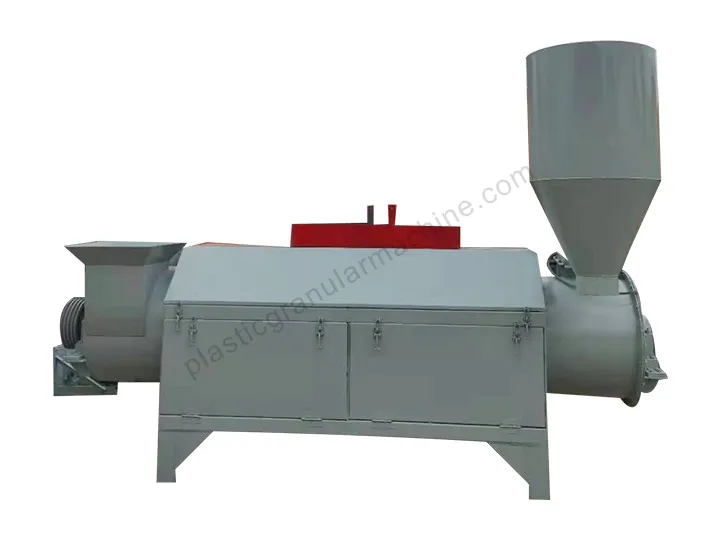

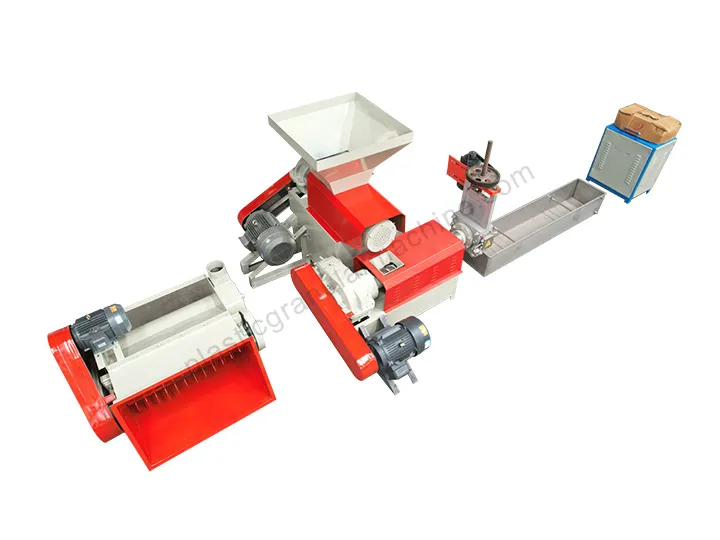

Melting and pelletizing

The cleaned plastic pellets are fed into the plastic pelletizing machine where they are heated and melted into liquid plastic. This process can be accomplished by heat and friction.

Cooling and Cutting

The melted plastic is extruded into filaments, which are cooling in a water tank and then cut into small plastic granules by a cutter to form plastic pellets. These pellets can be used to make new plastic products again.