OTR Tire Recycling |Complete Disposal Line

| Name | OTR tire recycling line |

| Raw Materials | OTR tires>1400 mm |

| Final Products | 10-40 mesh(0.63-2.5 mm) rubber powders |

| Capacity | Ccustomized |

| Services | On-site installation and operation guides |

| Warranty | One year |

You can now ask our project managers for technical details

With the rapid growth of mining, agriculture, and other heavy machinery industries, there is an increasing need to recycle and dispose of waste Off-The-Road (OTR) tires. These tires are too large and durable to be processed directly, which presents a challenge.

In response, we have developed two professional and efficient OTR tire recycling solutions. Through disintegration, crushing, grinding, and screening, we can produce high-purity rubber powder and effectively extract and separate steel wire and other materials.

Why Investing in OTR Plastic Recycling Is a Smart Move?

OTR tire recycling provides significant economic and environmental benefits. OTR tires, used in heavy-duty machinery like mining and agriculture, contain reusable materials such as rubber, steel wire, and nylon.

Recycling these OTR tires produces valuable rubber powder that can be utilized in asphalt, rubber floor tiles, and other products. This process not only reduces waste and pollution but also supports government initiatives and enhances the green image of businesses.

Key Features of Our Mining Tire Recycling Machines

- Super tire processing capacity: suitable for giant tires with a diameter of at least 1400 mm and able to process multi-tonne OTR tires continuously and stably.

- High-quality finished products: the rubber powder is at least 99% pure, fine and uniform; the steel wire can be sold directly to steel mills; the fibre can be used as fuel.

- The equipment performs well: OTR tyre recycling equipment is made of heavy, sturdy materials that are built to last. It is energy efficient and easy to maintain.

- Perfect service: customised equipment is available. We also provide technical support, on-site installation, a one-year free warranty, and a lifetime supply of parts.

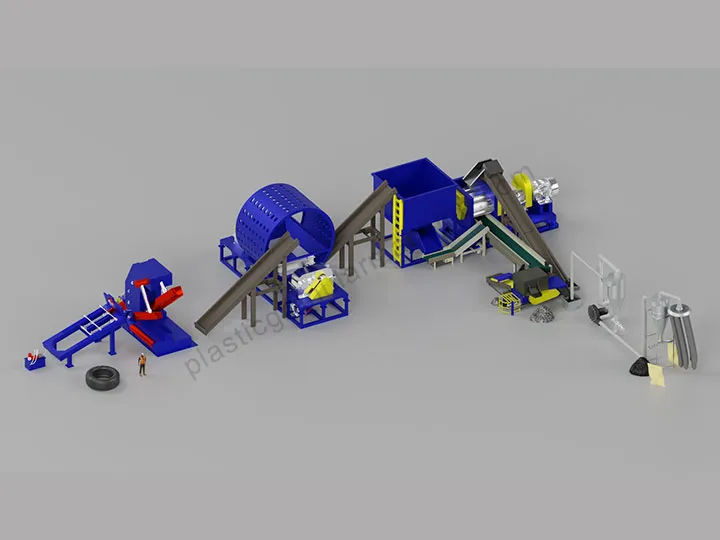

Two OTR Tire Recycling Solutions for Your Needs

OTR Tire Recycling Solution1:

Equipment: OTR drawing machine, OTR cutting machine, tire shredder, tire grinder and magnetic separator

Workflow:

- The OTR drawing machine efficiently removes the inner wall steel rims of tires using a hook clamping device and a traction device, thereby reducing wear and tear on subsequent equipment.

- The OTR cutting machine is hydraulically driven and cuts huge tyres into several pieces with a powerful cutting force for subsequent shredding.

- Tire shredders are available in a wide range of models. The tire chunks are shredded by twin shafts operating at low speed and high torque to produce uniform rubber chunks measuring approximately 50–100 mm.

- Fine grinding and multi-stage screening produce an output size of 10–40 mesh rubber powder (size freely adjustable), while removing powder mixed with fine steel wire. The rubber powder purity is higher than 99%.

Mining Tire Recycling Plant 2:

Equipment: OTR dismantling machine, OTR cutter machine, OTR tire steel wire separator, tire shredding machine, tire grinder and magnetic separation machines

Workflow:

- The rotary cutting device splits and disintegrates giant tires into bead, tread, and top parts, which reduces the burden of subsequent OTR tire recycling machines.

- The OTR tire cutting machine then cuts the disintegrated tire pieces into the proper size for the shredder.

- The OTR tire steel wire separator removes the steel rims from the bead opening of mining tires. The remaining rubber goes into the shredder for processing.

- The alloy blades of the tire shredder rotate relative to each other to shred the tire blocks into 50-100 mm pieces, which are easy to grind. The specific size can be set according to the shredder model.

- The tire shredder grinds the rubber into powder and uses a vibrating screen to achieve particle size grading. Additionally, the multi-stage magnetic separation device removes fine steel wires from the rubber powder, ensuring the purity of the finished product.

Get OTR Tire Recycling Machine Cost

If you’re in the mining industry, an industrial park, or an environmental organization, investing in an OTR tire recycling business is a sustainable and profitable choice. We have exported our OTR tire recycling equipment to Australia, Canada, Kenya, and many other countries, helping our customers solve the challenge of handling giant tires and dramatically increasing recycling efficiency.

If you are interested in improving your business, contact us today for the best recycling solution!